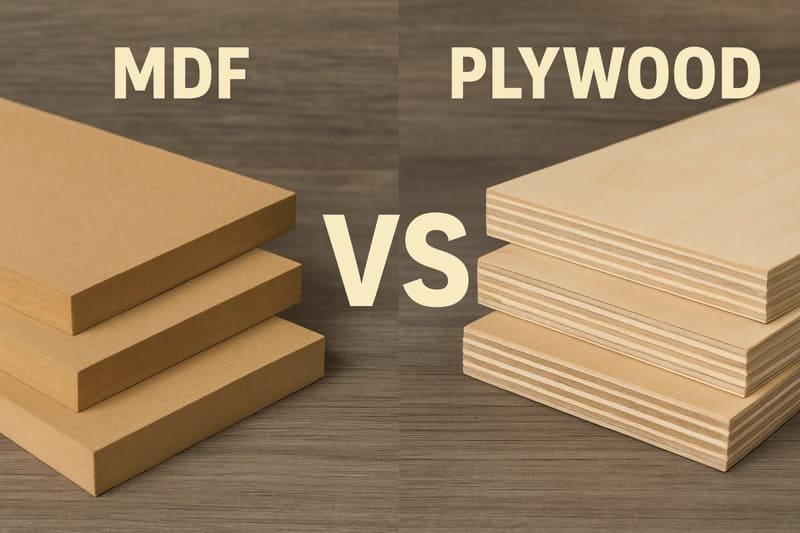

Featured image for MDF vs Plywood: Which Is Better for Furniture?

Choosing the right material for furniture can be overwhelming. I’ve faced the same dilemma: does MDF or plywood really make a difference in longevity, finish, and overall performance?

Plywood is generally better for furniture requiring strength, durability, or resistance to moisture, while MDF excels for smooth painted finishes, intricate designs, or cost-sensitive projects. The best option depends on your specific furniture application and environment.

Deciding between MDF and plywood ultimately comes down to understanding where and how my furniture will be used. In the next sections, I’ll break down the factors—like durability, finish, moisture exposure, and cost—that have shaped my choices, helping clarify which material will best meet different needs.

1. Which Material Lasts Longer: Plywood or MDF?

Frustrated by sagging shelves or damaged furniture? Many overlook the key difference between materials. Let's explore how your choice can affect durability and strength.

Plywood typically lasts longer and is structurally stronger than MDF. Its cross-laminated construction endures heavy use and resists warping. MDF, though dense, may sag or break under load or impact.

Understanding Plywood and MDF Construction

When I first built my own shelves, I faced Plywood1 and MDF2 at the hardware store. Both looked sturdy, but only one withstood the test of time and use.

Plywood forms by layering thin sheets of wood veneer. Each layer faces a different direction. This cross-lamination binds the structure, distributing weight evenly. If I put heavy books or objects on plywood shelves, the material supports the load. Warping rarely occurs, even after years.

MDF (medium-density fiberboard) is dense fiber pressed together with resin. It looks uniform and smooth. That finish is perfect for detailed paintwork or intricate designs. However, MDF does not have grain or layered structure. When I built a desk using MDF, I noticed sagging after placing a computer and books on top. Even minor impacts left dents or chipped edges.

Comparing Durability in Real Uses

I have used both materials in different rooms. Here is what I found about their behaviors in common scenarios:

| Feature | Plywood | MDF |

|---|---|---|

| Load-bearing | High | Medium/Low |

| Warping Resistance | Excellent | Poor |

| Impact Resistance | Good | Low |

| Suitability | Shelves, Beds, Seats | Decorative Panels |

| Lifespan | Longer | Shorter |

Why Plywood Outlasts MDF

Plywood’s structure maximizes strength. Each layer supports and compensates for weaknesses in others. This means even under daily stress, plywood furniture keeps its shape. I have noticed that plywood bed frames, even after years, seldom creak or bend out of shape.

MDF offers density and smoothness. However, its lack of layers makes it weaker under pressure. Heavy loads cause it to sag, sometimes irreversibly. If you drop an object on MDF, it may chip. In contrast, plywood often absorbs the shock.

How to Choose for Strength

I have learned that the right material depends on the use. For shelves, beds, or anything weight-bearing, plywood always performs better. For decorative applications or areas with little load, MDF works if I take care not to knock or overload it.

Final Thoughts

My personal projects taught me that the layered structure of plywood gives a clear advantage in durability and lifespan. For furniture that needs to handle daily use and heavy weight, plywood is the material that will last. MDF fits lighter, decorative needs but needs more care to prevent damage.

Plywood generally lasts longer and is more durable than MDF when used for load-bearing furniture.True

Plywood's cross-laminated structure provides greater strength, resistance to warping, and durability under heavy use compared to MDF.

MDF shelves are less likely to sag or break under heavy loads than plywood shelves.False

MDF is denser but lacks the layered structure of plywood, making it more susceptible to sagging or breaking under weight.

2. Which Material Offers the Best Painted Finish?

Uneven paint on furniture looks unprofessional. Poor surface preparation leads to disappointment. Choosing the right wood can guarantee crisp lines and a smooth, striking appearance3.

MDF provides the smoothest painted surface because of its uniform fibers; plywood’s visible grain makes it better for stained or natural finishes but less ideal for flawless paint applications.

Why Does MDF Outperform Plywood for Paint4?

MDF and plywood look similar at first. Yet their internal structures are very different. Each responds to paint in its own way.

MDF stands for medium-density fiberboard. This material is made by breaking wood down into fibers and then compressing them with resin under high pressure. As a result, MDF does not have a wood grain. When I run my fingertips across it, I feel only a smooth, even surface. This is not possible with plywood. Plywood consists of thin sheets of wood veneer layered together. The surface always has a visible grain, sometimes with knots or texture.

When painting cabinets or doors, this makes a big difference. I have often found MDF absorbs primer and paint at an even rate. The color always looks solid and uniform. There are no surprises—no hidden lines, patches, or inconsistent tones. Even at the corners and on detailed trim, MDF holds paint with crisp, sharp edges. That is why it is popular for modern or decorative pieces where a flawless finish is important.

With plywood, the grain is both a visual and a textural element. When I try to paint plywood, the grain remains visible beneath even several coats of paint. Sometimes the paint collects along the grain and dries bumpy. This is great if I am after a natural, textured look or want to use stain to highlight the pattern. But it is not ideal when the goal is a slick, modern finish.

Let’s compare the two side by side:

| Property | MDF Paint Finish | Plywood Paint Finish |

|---|---|---|

| Visible Grain | None | Always present |

| Paint Absorption | Very uniform | Varies across surface |

| Edge Quality | Crisp, clean when painted | May chip, less sharp |

| Suitable for Staining | No | Yes |

| Flawless Look | Easy to achieve | Difficult without grain show |

I remember working on a set of kitchen cabinet doors. The painted MDF ones had a mirror-like sheen. The plywood doors, in comparison, looked streaked because the finish followed the grain pattern.

MDF’s reliability for paint5 is its biggest advantage. However, it is important to know when plywood is better. If I want a rustic, traditional look6 or I plan to use transparent stains, plywood’s grain creates depth and interest.

Choosing Based on Your Aesthetic Goals

Think about your end goal. If you want a flawless, contemporary painted surface, MDF is my top recommendation because it avoids grain issues and delivers sharp, professional edges every time. Plywood is perfect if you want character, warmth, or a stained finish that celebrates natural wood patterns.

Deciding between them starts with the finish you desire. That finish shapes the entire look and feel of your project.

MDF provides a smoother and more flawless painted finish than plywood due to its lack of visible grain and uniform fibers.True

According to the content, MDF's structure allows for even paint absorption and crisp edges, making it ideal for sleek, modern painted finishes.

Plywood is the best choice for achieving a flawless, grain-free painted surface.False

Plywood has a visible wood grain that tends to show through paint, making it less suitable for a flawless painted finish compared to MDF.

3. What Material Handles Humidity Best in Your Home?

Humidity can ruin wood furniture fast. Choosing wrongly means warping and swelling. See why one engineered wood beats the other for wet zones in just minutes.

Plywood resists moisture far better than MDF, staying stable and strong even in humid or changing environments. For bathrooms, kitchens, or outdoor items, plywood is the safer, longer-lasting choice. MDF suits only dry, indoor spaces.

Understanding Moisture: How It Impacts Plywood and MDF

Moisture from air, spills, or steam acts fast. It enters the pores of wood products and can change their shape or make them lose strength. I once used MDF for shelves in my laundry room, thinking it was a cheap and smooth choice. After a long, rainy spring, I found bowed boards and mushy edges. The mistake taught me to check moisture ratings first.

MDF, or medium-density fiberboard, is made by pressing wood fibers and glue. It is dense and uniform. This makes it smooth for painting, but it has fine fibers that soak up water fast, both from the air and direct splashes. When MDF gets wet, it swells. It can even break down layer by layer. Humidity over 60% can start to damage it. If you need lasting indoor shelves or furniture, keep MDF far from windows, bathrooms, and kitchens.

Plywood is different. It comes from layers of thin wood veneer, glued together so each runs in a different direction. This cross-grain structure gives plywood its famous strength and helps it block moisture from moving through. It does still take in some water, but not the same as MDF. When exposed to wet air or splashes, plywood may slightly warp or discolor, but it rarely falls apart. Special grades, like exterior or marine plywood, have waterproof glue and tougher finishes. I used marine plywood under a sink after my bathroom shelf disaster. It held up perfect for years.

| Feature | Plywood | MDF |

|---|---|---|

| Moisture Resistance | High (esp. marine, ext) | Low |

| Warping | Rare if sealed | Common when wet |

| Swelling | Minimal (proper grade) | Rapid and severe |

| Best Use Locations | Kitchens, baths, ext. | Living rooms, offices |

Why the Difference Matters: Real-World Scenarios

Picture a kitchen cabinet with boiling pots and steam each day. MDF would slowly absorb the damp, doors could stick, and painted finish bubbles. Plywood, especially exterior grade, stays stable and firm even years later. For bathroom vanities or garages where you wash things and the air gets wet, only plywood stands up to the challenge.

In dry rooms—bedrooms, living rooms, offices—you can enjoy MDF’s smoothness and sharp corners. Just do not use it in basements, laundry rooms, or under windows that drip on cold mornings.

Selecting for Your Space: Smart Choices

Check your location first. Does the area get humid, see steamy air, or risk spills? Always go for plywood, and pick a water-resistant grade7. In any dry space where budget matters and looks come first, MDF remains a good choice. Picking wisely keeps your investment safe for years rather than months.

Realizing the risks of ignoring moisture resistance8 saved me hundreds of repair dollars and gave me peace of mind. Knowing the facts means you can make stronger, longer-lasting furniture choices for every room.

Plywood is more suitable than MDF for humid environments like bathrooms and kitchens.True

Plywood resists moisture better than MDF and remains stable in wet or changing conditions, making it ideal for humid areas.

MDF is the preferred material for outdoor projects and wet zones due to its high moisture resistance.False

MDF absorbs water quickly, swells, and breaks down in humid or wet areas, making it unsuitable for such applications.

4. Which Material Is Best for Detailed Woodwork Projects?

Have you struggled with wood that splinters or limits your creativity? Many people feel stuck by wood material choices. A smarter selection opens up new possibilities.

MDF is usually best for detailed woodwork projects needing precision cuts and custom shapes because it cuts cleanly without splinters. Plywood works better for jobs needing strength but may splinter during intricate work.

Understanding MDF and Plywood for Fine Work

When I first started playing around with woodworking, I wanted to make small carved boxes with curves and detailed edges. My first attempts with plywood left me frustrated. The surface chipped. The edges frayed. But once I switched to MDF, the difference was night and day.

What Makes MDF Easy to Machine?

MDF stands for medium-density fiberboard. Every part looks the same inside and out. If you cut it, route it, or carve into it, it behaves the same in all directions. There are no knots or changing patterns. This is why MDF does not splinter. The blade goes through cleanly. The edge holds sharp detail. I learned that many shops rely on MDF when they need exact shapes and fancy trims.

Challenges With Plywood

Plywood uses layers of thin wood sheets glued together. The surface layer is smooth, but the inside layers run in different directions. If I cut across those inner grain lines, they can fall apart or split away. When I tried to carve shapes into plywood, the tool sometimes caught a corner and tore a strip loose. This can ruin a piece or make it look rough.

How MDF and Plywood Work for Design Flexibility

Let us look at a table to compare their strengths:

| Feature | MDF | Plywood |

|---|---|---|

| Cutting Cleanliness | Smooth, no splinters | Possible splintering |

| Holds Fine Edge | Excellent | Fair, may chip |

| Custom Carving | Easy to shape | Can break along edges |

| Strength Along Face | Medium | High |

| Stability | Stable indoors | Good, stable for large pieces |

I often get people asking when they should use MDF. If the job needs detailed cuts or a lot of trim work—door panels, fancy moldings, or custom shelving—MDF gives you more freedom. Shapers, routers, and scroll saws go through it without the blade catching. If you have ever wanted to try layered inlays, carved panels, or custom cabinetry features, MDF is simpler to work with.

For heavy shelves, big cabinets, or when I needed something harder to break, I chose plywood instead. The surface can be finished nicely but it just does not like intricate, deep shaping. Still, plywood is trustworthy for basic boxy shapes, supporting a lot of weight, or surfaces that need to stay strong for a long time.

Personal Insights: Finding Out What Works

When I worked on a bookshelf with an arched top and carved trim, MDF made the process easy. I could cut all curves and shapes by hand and the material stayed solid. But, when I built a long worktable for my garage, plywood’s surface strength mattered more. I learned you have to pick the right board for the right job.

Choosing MDF for detail lets your creativity show. The material helps you avoid headaches that come with chips, splinters, or ruined edges. For detailed projects, I always reach for MDF first. It makes the work simpler and cleaner. Knowing the right board for your project will save time and help you build with confidence.

MDF is ideal for detailed woodwork projects because it cuts cleanly without splintering.True

MDF is described as cutting cleanly and holding sharp detail, making it suitable for precision cuts and custom shapes in detailed work.

Plywood is better than MDF for projects requiring intricate carving and fine edges.False

The content states that plywood tends to splinter and chip during intricate work, making it less suitable than MDF for projects needing detailed carving and fine edges.

5. Which Material Gives More Value: MDF or Plywood?

Are you worried about overspending or choosing a material that will not last? Let us break down the real cost and value between MDF and plywood.

MDF costs less upfront, but plywood offers better long-term value for furniture that gets used often. Choosing between the two requires balancing price, weight for shipping, and how long you expect the product to last.

Understanding the Real Cost of MDF and Plywood

As I weigh construction materials, I always ask which option suits both the project’s needs and the budget. Both MDF and plywood seem to fit many jobs, but their differences shape the outcome.

Comparing Upfront and Long-Term Costs

Most people choose MDF because it is less expensive to purchase. I have used it for projects where the look and budget are important. MDF makes sense for shelves, cabinets, or pieces that will not face heavy use. It arrives smooth, takes paint well, and is great for flat-pack or assembled furniture made in large numbers.

Plywood, on the other hand, costs more at the start. Many see this as a drawback. But if you expect the furniture to last for years and stand up to constant opening and closing, I find plywood gives peace of mind. The layers in plywood make it stronger and more resistant to warping or cracking. The extra money spent originally can mean fewer repairs, replacements, or complaints down the road.

The Influence of Weight and Shipping

Weight plays a big role, especially if shipping costs matter. MDF is denser, so it can weigh more than plywood of the same thickness. This adds up quickly when sending bulk orders or furnishing multiple rooms. I usually factor freight costs into my estimates.

How Usage Impacts Value

Think about how often the piece will be used. MDF might work well for a decorative item or a fixture you rarely touch. For a desk or a cabinet door that opens every day, the strength of plywood often justifies the extra spend.

Decision Table: MDF vs Plywood Value Factors

| Factor | MDF | Plywood |

|---|---|---|

| Initial Price | Lower | Higher |

| Long-Term Durability | Moderate | Excellent |

| Weight (for shipping) | Heavier (dense) | Lighter (same thickness) |

| Visual Surface | Smooth, good for painting | Wood grain, can stain/paint |

| Frequent-Use Suitability | Not ideal | Very good |

My Verdict

Every decision should match the project’s needs. Tight budgets, short-term use, or mass production push me toward MDF. For heirlooms, heavy use, or when shipping needs to stay low, plywood earns its keep. Knowing the life cycle of the furniture helps justify the price difference.

So, for the best value, choose MDF when low cost is king and the furniture will not see hard use. Pick plywood if you want longer-lasting, sturdy results that save money on repairs and shipping in the long run. Every project has its own “right” answer, but checking the full value equation keeps surprises away.

Plywood generally offers better long-term value for frequently used furniture compared to MDF.True

According to the content, plywood is stronger, more durable, and more suitable for items that undergo constant use, making it a better investment for long-term value.

MDF is lighter than plywood of the same thickness, making it more cost-effective to ship in bulk.False

The content states that MDF is actually heavier and denser than plywood of the same thickness, which can increase shipping costs.

6. Which Is More Eco-Friendly: MDF or Plywood?

Want to make the right green choice but facing confusing options? Harmful emissions and greenwashing claims can complicate eco-friendly wood selection. You can protect health and planet with the right knowledge.

MDF and plywood can both be eco-friendly if made with certified low-emission adhesives and responsible sourcing, but key differences in materials, emissions, and certifications impact their environmental footprint.

Understanding MDF and Plywood: What Sets Them Apart?

Choosing the right material for environmentally conscious projects means understanding what lies beneath the surface. Let’s look closer at how MDF and plywood are produced and what these processes mean for the planet.

MDF: Recycled Content and Emission Challenges

MDF, or Medium Density Fiberboard, often includes recycled wood fibers. I like that using waste wood can reduce the need for fresh timber. But you need to check what holds it together. Standard MDF traditionally uses urea-formaldehyde resin. Formaldehyde can leak out as volatile organic compounds (VOCs), especially early in product life.

Careful consumers should search for MDF labeled E0 or E19, which signals very low or minimal formaldehyde emissions. Many of my projects have relied on E0-certified MDF to ensure healthier indoor air and less environmental impact. It isn’t just about the wood content—the glue really matters when thinking green.

Plywood: Fast-Growing Sources and Certifications

Plywood is made by gluing together sheets of wood veneer. Sourcing practices in plywood production vary widely. Some plywood comes from fast-growing plantation species, which regrow quickly and help maintain forest cover. But plywood can also use hardwoods from natural forests if no controls are in place.

Responsible manufacturers now offer plywood certified by the Forest Stewardship Council (FSC)10. This assures buyers that wood comes from forests managed with strict environmental and social standards. I have found that certified plywood products usually carry a visible FSC logo and documentation, which makes informed purchase decisions simpler.

Environmental Comparison Table

| Aspect | MDF | Plywood |

|---|---|---|

| Main Material Source | Wood fibers, often recycled | Large veneer sheets |

| Resin/Adhesive Used | Often urea-formaldehyde (check for E0/E1) | Varies, low-emission options available |

| VOC Emissions | Can be high unless certified E0/E1 | Can be low with the right adhesives |

| Sustainable Certifications | E0/E1 for low VOC, some recycled content claims | FSC certification, some plantation sourcing |

| Carbon Footprint | Lower if recycled content high and low-VOC resin | Lower with FSC, plantation, low-emission resin |

Key Buying Checklist

1. Check for E0 or E1 Certification11

When I select MDF, I always ask for laboratory results or certification mentioning E0 or E1. This reduces formaldehyde harm inside buildings.

2. Look for FSC Certification on Plywood12

FSC-labeled plywood gives confidence that forests are protected and communities respected.

3. Inquire About Recycled Content

More recycled wood in MDF means less waste and a smaller carbon step.

4. Ask About Fast-Growing Timbers

Sourcing from plantations for plywood helps avoid deforestation and supports responsible wood use.

Conclusion

There is no one-size-fits-all answer. Both MDF and plywood can be sustainable, but you should demand independent certifications. Think about recycled content, emission levels, and responsible sourcing. When I follow these guidelines, I find products that support both my project’s quality and the planet’s future.

Both MDF and plywood can be eco-friendly if they are produced using certified low-emission adhesives and responsibly sourced wood.True

The content states that both materials may be eco-friendly, provided manufacturers use low-emission adhesives and practice responsible sourcing.

All MDF and plywood products on the market are automatically sustainable and emit no harmful chemicals.False

The text explains that some MDF and plywood can emit harmful VOCs and may not be sustainably sourced unless they have appropriate certifications.

7. What Impacts Shipping Costs: MDF or Plywood?

Furniture can arrive damaged, delayed, or over budget because of hidden shipping factors. This frustrates everyone. Knowing the material differences gives control back.

Plywood’s lighter weight and durability lower shipping costs and make assembly easier, while MDF’s heavier density increases transport expenses and risk during handling. Plywood handles drops better and resists fastener cracks for assembly.

The Real Cost: Shipping and Handling Explained

Every time I worked with bulky panels, the type of board made a clear difference. When I first shipped MDF boards13, the extra weight was obvious. My back hurt from the strain, and my freight bill was higher than expected. On another job, plywood panels14 felt easier to manage, especially in tight spaces. These details matter.

Weight and Density Comparison

The main factor is weight. MDF, with its high density, can weigh over 30% more than a same-size plywood sheet. This impacts not just my ability to carry the material, but the cost of moving it over long distances.

| Panel Type | Average Weight (per 4’x8’ sheet, ¾”) | Impact on Shipping |

|---|---|---|

| MDF | 85 - 95 lbs | Higher shipping cost |

| Plywood | 55 - 70 lbs | Lower shipping cost |

I found that when stacking hundreds of sheets, the difference in total weight could shift a shipment from one I found that when stacking hundreds of sheets, the difference in total weight could shift a shipment from one freight class1 to a more expensive one. More weight means higher fuel costs and stricter handling protocols. This was especially important when shipping overseas.

Handling Challenges

Heavy boards strain workers and equipment. During one building project, cases of MDF were difficult to move through cluttered storage areas. Plywood not only moved faster but also suffered fewer dings from drops or bumps. It cushioned impact better. In contrast, MDF’s density made it both heavy and brittle along edges.

Assembly Perks

When it comes to putting furniture together, plywood stands out. One customer told me how their team cracked several MDF panels while screwing pieces together. Plywood’s structure holds screws better and resists splitting. That builds confidence in assembly for both professionals and DIY users.

Risk of Damage

I have seen both panel types take a fall. Plywood’s lighter weight reduces impact speed. It flexes instead of snapping, keeping corners and edges intact. In mass-produced shipping, this means fewer units damaged and less waste.

Efficiency for Bulk Orders

For large-scale shipments, plywood keeps costs down. For example, loading a single truck, I fit more plywood sheets within safe weight limits. That means fewer vehicles, less fuel, and reduced risk of injury or product loss.

Choosing the Right Material

Selecting between MDF and plywood is about more than looks or cost per sheet. It’s about the entire journey from warehouse to assembly. By weighing these factors, I have helped many projects stay on time, on budget, and free from surprises. The right panel is the one that moves smoothly from start to finish.

Handling Challenges

Heavy boards strain workers and equipment. During one building project, cases of MDF were difficult to move through cluttered storage areas. Plywood not only moved faster but also suffered fewer dings from drops or bumps. It cushioned impact better. In contrast, MDF’s density made it both heavy and brittle along edges.

Assembly Perks

When it comes to putting furniture together, plywood stands out. One customer told me how their team cracked several MDF panels while screwing pieces together. Plywood’s structure holds screws better and resists splitting. That builds confidence in assembly for both professionals and DIY users.

Risk of Damage

I have seen both panel types take a fall. Plywood’s lighter weight reduces impact speed. It flexes instead of snapping, keeping corners and edges intact. In mass-produced shipping, this means fewer units damaged and less waste.

Efficiency for Bulk Orders

For large-scale shipments, plywood keeps costs down. For example, loading a single truck, I fit more plywood sheets within safe weight limits. That means fewer vehicles, less fuel, and reduced risk of injury or product loss.

Choosing the Right Material

Selecting between MDF and plywood is about more than looks or cost per sheet. It’s about the entire journey from warehouse to assembly. By weighing these factors, I have helped many projects stay on time, on budget, and free from surprises. The right panel is the one that moves smoothly from start to finish.

Plywood sheets typically cost less to ship than MDF sheets due to their lighter weight.True

The content states that plywood is lighter than MDF, leading to lower shipping costs and easier handling.

MDF resists cracking and handles fasteners better than plywood during furniture assembly.False

The content explains that plywood resists cracking and holds screws better than MDF, which is more prone to damage when assembling.

Conclusion

Choose plywood for strength, durability, moisture resistance15, and natural finishes; opt for MDF for smooth paintable surfaces, intricate detailing, and budget-friendly indoor furniture projects16.

-

Explore the benefits of plywood, including its durability and strength, to make informed choices for your furniture projects. ↩ ↩

-

Learn about the drawbacks of MDF, such as sagging and damage, to understand when to avoid this material in your projects. ↩

-

Learn techniques to achieve a smooth, striking appearance in your furniture projects for professional results. ↩

-

Discover the advantages of MDF over plywood for painting, ensuring a flawless finish on your furniture. ↩

-

Explore this link to understand why MDF is a top choice for painted surfaces, ensuring a flawless finish. ↩

-

Discover tips and techniques for creating a warm, rustic aesthetic using plywood in your kitchen. ↩

-

Exploring water-resistant grades in plywood can help you select durable materials that withstand moisture, ensuring longevity. ↩

-

Understanding moisture resistance is crucial for making informed furniture choices that last, especially in humid areas. ↩

-

Understanding E0 and E1 certifications helps you choose healthier MDF options, ensuring lower formaldehyde emissions for better indoor air quality. ↩

-

Exploring FSC certification can guide you to responsibly sourced plywood, ensuring your choices support sustainable forestry practices. ↩

-

Understanding E0 and E1 certifications is crucial for ensuring low formaldehyde emissions in your building materials. ↩

-

Exploring FSC certification helps you choose plywood that supports sustainable forestry and community welfare. ↩

-

Exploring this link will provide insights into the pros and cons of using MDF boards, helping you make informed shipping decisions. ↩

-

This resource will help you understand the benefits of plywood panels, making your shipping process smoother and more efficient. ↩

-

Understanding moisture resistance in plywood can help you choose the right material for your projects, ensuring longevity and durability. ↩

-

Exploring budget-friendly projects can inspire creativity and help you maximize your resources while achieving beautiful results. ↩

Published: 2025-07-23