Featured image for 3 Ideal Situations to Use MDF for Strong Bookshelves

Building the perfect bookshelf has been my journey of discovery, balancing aesthetics, cost, and durability. MDF (Medium-Density Fiberboard) surfaced as a standout choice, resolving common shelving dilemmas with its affordability and versatility.

MDF serves excellently for bookshelves in specific settings: light to moderate loads in stable climates, decorative finishes like paint, and budget-focused mass production, combining strength and design flexibility.

You might wonder: When exactly should MDF be your go-to option for strong bookshelves? Understanding the scenarios, from home studies to decorative and budget applications, reveals MDF's true potential, allowing you to choose wisely. Here's how MDF can meet and exceed your shelving expectations by matching functionality, aesthetics, and budget needs.

1. When Is MDF the Best Choice for Strong, Stylish Bookshelves?

Struggling to balance cost, strength, and style when picking bookshelf materials? This challenge can lead to weak shelves or overspending. MDF offers unique advantages in some scenarios.

MDF is the best material for strong bookshelves when you need maximum design flexibility, a smooth finish, or cost-effective construction in stable environments. Its structure makes it suitable for specific shelving needs.

Understanding MDF’s Strengths: When and Why It Excels

I have built several bookshelves for clients and my own study. Each time, the choice of material made a big difference in long-term satisfaction. MDF is not just about saving money. I have found it excels in three specific scenarios.

1. Uniform Loads in Climate-Controlled Rooms

MDF is a strong, engineered wood product made from fine wood fibers. The fibers bond with resin under heat and pressure. This gives MDF a smooth, dense structure. It supports uniform, moderate weights very well. When I use MDF in rooms with stable temperature and low humidity, bookshelves stay flat and resist warping. In many homes and offices, climate control makes MDF ideal. It does not react much to small changes in temperature or humidity.

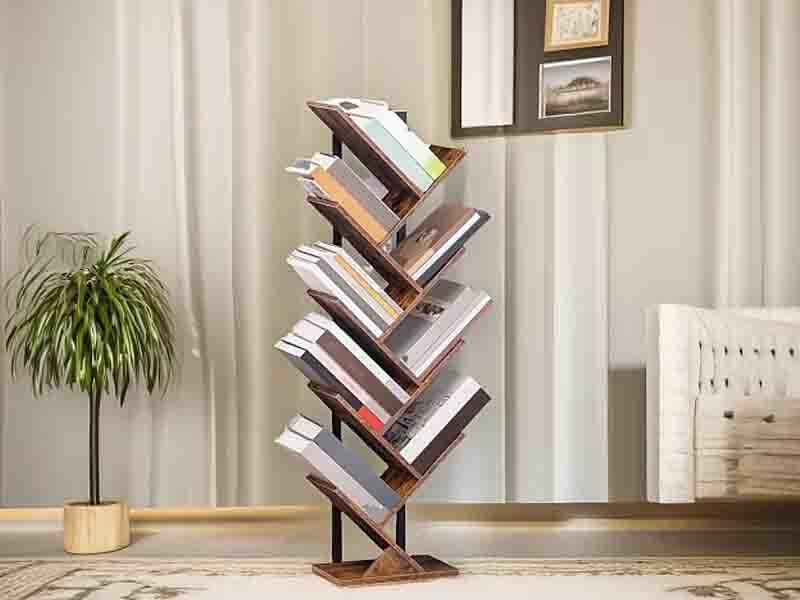

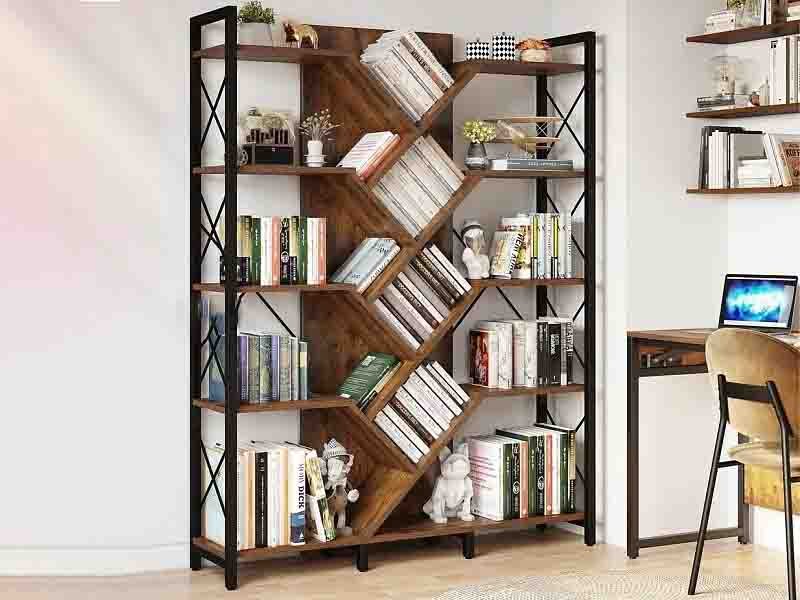

2. Custom Designs with Stylish Finishes

Sometimes a client asks for curved, cut-out, or painted shelves. MDF allows me to shape and rout edges easily. The fine grain means there are no knots or grain patterns to disrupt painting or finishing. Any color or lacquer looks smooth. For modern or decorative shelves, MDF is hard to beat. With a flawless surface, paint and even veneers look richer and more even than on many hardwoods.

3. Budget-Conscious Builds without Sacrificing Appearance

Solid hardwood can be expensive, especially for large units. When a project’s budget is tight, MDF helps me deliver attractive, robust shelves at a lower cost. This is especially true for built-in shelves or library walls where material cost multiplies fast. As long as I follow good shelf design—like adding proper bracing and not overspanning—MDF holds up years longer than low-quality plywood or particleboard.

How MDF Compares in Common Bookshelf Priorities

| Requirement | MDF | Solid Wood | Plywood |

|---|---|---|---|

| Surface Smoothness | Excellent | Varies | Good |

| Custom Shaping | Easy | Moderate | Hard |

| Resistance to Warping | Good (if stable) | Good (depends) | Fair |

| Cost | Low | High | Medium |

| Paint Finish | Excellent | Variable | Good |

Practical Considerations for MDF Bookshelves

I always protect MDF from moisture1. I use proper paint or sealant and avoid placing MDF shelves in damp areas like basements. For longer shelves, I add a strong face frame2 or mid-span support. These practices make MDF a strong and beautiful choice within its best scenarios. For bookshelves that need flawless paint and fit a budget, or a room that stays dry and comfortable, MDF gives both performance and value.

By knowing when MDF fits best, anyone can build bookshelves that last and look impressive, without overspending.

MDF is an ideal material for bookshelves in stable environments due to its resistance to warping.True

MDF's dense structure and ability to maintain shape in climate-controlled rooms make it resistant to warping under uniform loads.

MDF is the most expensive option for building bookshelves.False

MDF is typically less expensive than solid hardwood, making it a budget-friendly choice for bookshelf construction.

2. Is MDF the Best Choice for Light to Moderate Bookshelf Loads?

Too many people choose the wrong shelf material and end up with sagging or warped shelves3. This can make important rooms look messy and put items at risk. MDF offers a simple solution.

MDF works well for shelves handling light to moderate book loads in climate-controlled spaces. With a stable environment and the right thickness, MDF shelves offer strength, durability, and a smooth finish for everyday needs.

Understanding MDF’s Role in Everyday Bookshelves

Medium Density Fiberboard (MDF)4 is often overlooked when people shop for shelving. Still, I learned the hard way that solid wood sometimes warps or cracks, especially when the room changes temperature or humidity. MDF solves many of these problems by offering a consistent and predictable performance in climate-controlled interiors like homes or offices.

Why MDF Excels in Light to Moderate Bookloads

MDF is manufactured with uniform density throughout. This makes it an ideal candidate for situations where load demands are not extreme. For example, family rooms filled with paperbacks, workspaces displaying lightweight binders, or kids’ rooms organizing picture books fall well within MDF’s capabilities. The key is knowing the limits. I always calculate the number of books and estimate the overall load before choosing a shelf thickness5.

Environmental Stability Matters

MDF shelves cope best in environments with stable humidity (30-55%) and moderate temperatures (16-24°C). Extreme temperature or moisture swings can make even engineered boards swell or lose strength. In my experience, shelves kept indoors, away from heating vents and not exposed to direct sunlight stay straight and stable for years.

Calculating the Right Thickness and Span

Choosing the right board thickness is essential. MDF shelves for books (not heavier than 30kg per meter) need to be at least 18 mm thick. If I plan for a span without a center support, I make sure it does not exceed 900 mm. This prevents sagging and preserves the shelf’s look and strength for a long time.

| Shelf Application | Max Load (kg/m) | Span w/o Center Support (mm) | Recommended MDF Thickness (mm) | Humidity Range (%) | Temp Range (°C) |

|---|---|---|---|---|---|

| Living Room/Study | 30 | 900 | 18–25 | 30–55 | 16–24 |

| Corporate Display | 30 | 900 | 18–25 | 30–55 | 16–24 |

| Kid’s Room Bookshelves | 20 | 900 | 18–22 | 30–55 | 16–24 |

Weighing MDF Against Other Materials

Some people think plywood or solid wood is always better. In certain demanding or damp areas, that may be true. For normal, climate-controlled rooms6 and when shelf loads are not too big, MDF holds its shape. Its smooth surface gives a clean, modern look, which suits many home or office designs. I noticed the finish is especially good for painted shelves.

My Experience with MDF Shelving

I used MDF for my office library. The shelves have been full of hardcovers for three years now, with no visible sag. My children’s playroom has MDF shelves, too. Even with daily use, they keep their shape and finish.

When choosing a shelf, you should focus on your space, climate, and weight needs. If you need sturdy and efficient solutions for common home or office settings, MDF—of the right thickness—can save you money and serve well for years.

MDF is not for everywhere. But for managed interiors and typical book storage, it remains one of my top choices.

MDF is suitable for light to moderate loads in climate-controlled environments.True

MDF's uniform density and stability make it ideal for shelving in stable humidity and temperature conditions, allowing it to handle light to moderate book loads effectively.

MDF shelves can support any weight of books without sagging.False

MDF shelves are limited to handling up to 30 kg per meter, and exceeding this weight can cause sagging and warping over time.

3. Why Is MDF the Top Choice for Decorative Painted Bookshelves?

Traditional bookshelf materials often show grain or require hours of prep. This slows projects and limits finish options. MDF solves these frustrations and delivers premium, flawless results7.

MDF is superior for decorative or painted bookshelves because it has no wood grain and an ultra-smooth surface (Ra 3.2-6.3 µm), allowing for crisp details and perfect paint or veneer application with minimal prep.

MDF’s Surface: The Secret to Flawless Decorative Results

I have worked with both hardwoods and plywood for shelving over the years. Each material poses unique challenges when a project demands a sophisticated, eye-catching look. Visible grain can ruin the sleekness of a colored finish. Minor sanding mistakes might show through a glossy paint. Time spent prepping textured surfaces always adds up in cost and hassle.

MDF, or Medium Density Fiberboard, flips this issue. Its manufacturing process breaks wood fibers down so thoroughly that the result feels nearly as smooth as glass. After sanding, the surface roughness sits between 3.2 and 6.3 micrometers—almost invisible to the eye and hand. No grain stands in the way of crisp shadows or a glass-like shine.

Where MDF Outshines Other Materials

Let’s compare shelf materials for premium finishes:

| Property | MDF | Hardwood | Plywood |

|---|---|---|---|

| Surface Smoothness | Exceptionally smooth | Grain, pores, texture | Grain may show, some voids |

| Grain Telegraph | None | High risk | Medium risk |

| Prep Time for Paint | Minimal | Extensive | Medium |

| Intricate Profiles | Crisp, clean edges | Requires extra sanding | Edges may chip/tear |

| Finish Uniformity | High | Inconsistent | Moderate |

When I first used MDF for a built-in, the client wanted a rich blue high-gloss finish8 with chamfered details. With hardwood, I would have filled and sanded the grain, worried it might telegraph through the paint, then spent extra time at every profile change. With MDF, my base required only a quick prime and sand. The paint coat sat flat, no interruptions, with every corner perfectly sharp.

Best Use Cases for MDF Decorative Bookshelves

Some bookshelf projects specifically demand what MDF offers:

- CNC-milled or routed profiles. Curves and angles stay sharp. MDF does not chip out.

- High-gloss or matte paint. No risk of grain pattern appearing under light.

- Veneered finishes for architectural focal points. MDF’s flatness makes for perfect adhesion.

- Large display walls in modern homes. Surfaces stay uniform edge-to-edge.

Trouble with Traditional Choices

Let’s not ignore what happens if you try plywood or hardwood when looks matter most. A hardwood shelf might show open pores and subtle grain lines even under primer. You can sand, fill, and repeat coat after coat. The end result can still highlight the material’s natural pattern—great for stain, not ideal for solid color or lacquer.

For plywood, the problem ratchets up when intricate joinery is in play. Edges can splinter, and the face often telegraphs seams or underlying patterns. Achieving a modern, slick look means substantial material prep. That translates into more labor and more cost.

My Takeaway

Whenever a client or designer requests a dramatic painted bookshelf that will anchor a room, I default to MDF. No other option provides the necessary surface quality as reliably, and no material streamlines the painting or veneering process as effectively. In my experience, it is the only way to guarantee an immaculate, high-end decorative result—no matter how detailed the design.

MDF has a smooth surface that allows for flawless paint application.True

MDF's ultra-smooth surface enables crisp details and perfect paint application without visible grain interference.

MDF is not suitable for high-gloss finishes due to its rough texture.False

MDF is ideal for high-gloss finishes as it has a very smooth surface that supports even application.

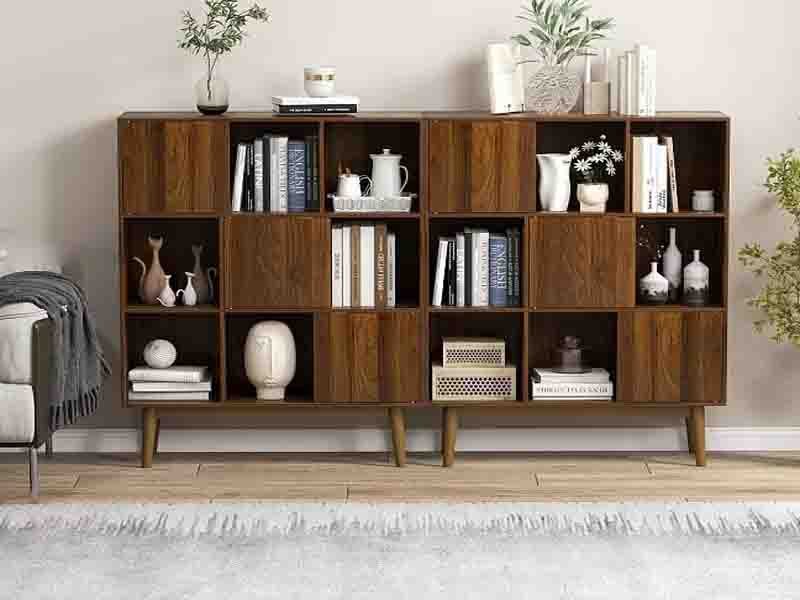

4. Which Material Is Best for Affordable, Durable Book Furniture?

Many buy cheap shelves that break or sag over time. This leads to frustration and waste. MDF solves these problems—delivering both low cost and reliable strength for book furniture.

MDF is the best choice for making durable, budget-friendly book furniture because it combines strong structural properties and affordability, while also allowing for fast manufacturing, reliable assembly, and improved durability with edge-banding or lamination.

Why MDF Stands Out for Mass-Produced Book Furniture

When people shop for mass-market bookshelves9, they want something long-lasting, attractive, and affordable. This is tough to achieve with many materials. I remember assembling my first bookshelf with particleboard10 panels. After a year packed with heavy books, the shelves sagged, and the screw holes loosened. That experience taught me to look beyond the lowest price.

MDF vs. Other Materials: The Cost and Strength Equation

Cost matters in large-scale furniture production. When I compare materials, high-quality hardwoods often cost at least 35% more than medium-density fiberboard (MDF). Even plywood, another popular option, can cost 15–30% more for the same thickness. When making hundreds or thousands of units, those savings make a real difference.

But cost is not the whole story. Particleboard, the lowest-cost engineered wood, cannot hold screws as well as MDF. Its holding power is less than 60% of what MDF offers. This limits how much weight a shelf can hold and often leads to joint failures. I have seen shelves bow under the weight of books or even come apart where particleboard screws pull free from the panel.

Here is a simple comparison:

| Material | Cost (per unit) | Screw-Holding Power | Sag Resistance | Durability when Laminated | Recommended for Bookshelves? |

|---|---|---|---|---|---|

| MDF | Low | High | Good | High | Yes |

| Particleboard | Lowest | Low | Low | Moderate | No |

| Plywood | Medium | Medium-High | Good | High | Sometimes |

| Hardwood | High | High | Very Good | High | Yes, but not affordable |

The Role of Edge-Banding and Laminates

MDF’s surface is smooth, but it needs extra protection against moisture and chipping. Most mass-produced shelves use edge-banding and durable plastic laminates11. This gives the shelf an attractive, easy-to-clean finish and adds protection. Laminating also blocks moisture from entering the fiberboard, so the shelves last longer in rooms with humidity.

Fast, Consistent Machining Matters

Mass production demands speed and accuracy.MDF machines easily12 and produces a smooth result every time. I have watched assembly lines cut MDF to the exact size for shelf panels. Screw holes and fittings stay consistent. Assembly is fast because the panels do not split or chip like lower-grade particleboard can.

Balancing Quality and Cost in Book Furniture

Book furniture made from MDF is a balance between being affordable and serving well under daily use13. The strong surface resists scratches. Shelves hold up under weight. Manufacturers can control costs without sacrificing key features for buyers who care about durability.

I came to trust MDF bookshelves for these reasons. Whether in schools, offices, or homes, MDF offers consistent performance at a price many people can afford. It outperforms particleboard in key areas and offers cost savings over hardwood and most plywood, making it the top choice for budget-conscious, mass-produced book furniture.

MDF is an affordable and durable material for book furniture.True

MDF combines strong structural properties with low cost, making it ideal for budget-friendly and durable book furniture.

Particleboard is more durable than MDF for supporting heavy books.False

Particleboard has lower screw-holding power and sag resistance than MDF, making it less suitable for supporting heavy books.

5. Can MDF Really Handle Heavy Loads and Humid Environments?

Making the wrong choice in shelving or cabinetry can lead to sagging, damage, or costly repairs. Ignoring technical limits puts projects at risk. Get informed to avoid preventable failures.

MDF can support moderate weights and dry conditions when used correctly, but it risks sagging under heavy loads or long spans and may swell if exposed to moisture—proper reinforcement and moisture protection are key.

Understanding the Limits of MDF: More Than Just a Budget Board

Medium Density Fibreboard, known as MDF, earns its reputation as a versatile and cost-effective material for furniture and cabinetry. But many wonder: how far can this material go before it fails? I have spent years working with wood panels in various furniture projects. The technical parameters and hands-on performance of MDF never ceased to impress—or, at times, disappoint—depending on the use.

The Numbers Behind Performance

MDF boasts a typical bending strength of 22-28 MPa14, referencing the EN 622-5 standard. In practical terms, this supports use in decorative shelving, cabinet sides, or wardrobe panels where loads remain light to moderate. Thickness and shelf span are decisive. If I select a thicker MDF sheet or design shorter spans, I can depend on a shelf to last for years—even under the weight of dishes or moderate book collections.

However, problems start when these rules are overlooked. MDF sags if forced to support excessive weight or if a shelf span goes beyond 900mm without added bracing. I learned this lesson early, watching a friend’s homemade library shelf bow noticeably after filling it with oversized art books.

Moisture: A Necessary Caution

MDF is made from small wood fibers mixed with resin. These fibers act like sponges when water is present. Even minor water exposure can cause swelling, a problem that ruins painted finishes and destroys the structure. In my own kitchen renovation, I specified Moisture Resistant MDF15 (MR-MDF) for adjacent areas to the sink and sealed all exposed edges. That careful planning made the difference after a small plumbing leak—standard MDF would not have survived.

Table: Comparing MDF Strength and Limits

| Characteristic | Standard MDF | MR-MDF | Notes |

|---|---|---|---|

| Bending Strength (MPa) | 22-28 | 23-31 | MR-MDF slightly stronger |

| Max Unsupported Shelf Span* | 900mm | 900mm | Reinforce for longer spans |

| Moisture Resistance | Low | Higher | Use MR-MDF in humid areas |

| Suitable for Heavy Loads | No (alone) | No (alone) | Use solid lipping/engineered system |

*assuming 19mm thickness, light-moderate loads

Using MDF Wisely

Based on my experience, MDF needs support when loads are high or shelves are long. I add a solid wood lip or design a dual-layer sandwich when building bookcases for heavy items. This prevents sagging and gives peace of mind. For kitchens or bathrooms, MR-MDF16 or thorough edge sealing17 is a required step.

Informed Choices Prevent Headaches

Ignoring technical strengths and limits adds risk to every project. Knowing these figures helps me plan smarter, save money, and deliver results that last. MDF works best in dry, supported applications where there is no surprise moisture or overloading. When I respect these rules, clients stay happy—and so do I.

MDF can sag if exposed to excessive weight or long spans without reinforcement.True

MDF has limitations in strength; exceeding these can cause sagging, especially over unsupported lengths.

MDF is suitable for heavy loads without any need for reinforcement or moisture protection.False

MDF cannot support heavy loads alone and requires reinforcement and moisture protection to avoid damage.

6. How Do Experts Build Strong, Lasting MDF Bookshelves?

Many bookshelves risk sagging or early failure from improper construction. Weak edges, span lengths, and poor sealing compound the problem. Use the proven methods experts trust for reliable, professional MDF shelving.

Experts build strong MDF bookshelves by limiting shelf spans, adding solid wood edge lipping, using robust hardware, and sealing all edges. These strategies maximize MDF's strengths, prevent sagging and moisture issues, and extend shelf lifespan.

Why Limiting Unsupported Span is Crucial

I learned this the hard way. My first DIY bookshelf used 19mm MDF shelves but ignored the span recommendation. Heavy textbooks caused the shelf to bow within a few months. Professional guidance is clear: unsupported spans for 19mm MDF must stay below 900mm for standard use, and below 700mm for heavy loads.

Let us look at a table showing how span recommendations change with loading:

| Usage Level | MDF Thickness | Maximum Span (mm) |

|---|---|---|

| Light/Normal | 19mm | 900 |

| Heavy | 19mm | 700 |

Limiting shelf span effectively distributes book weight and reduces bending. When I switched to 700mm spans18 for my reference shelf, sagging stopped for good.

The Power of Edge Lipping19

Front edges take the most pressure. Exposed MDF edges are weak, especially under load. Professional makers always bond solid wood strips (20-30mm thick) to the front edge. This simple method increased the stiffness of my shelves more than I expected.

Edge lipping adds another benefit. It protects the absorbent MDF core from knocks and chipping. With a robust edge, my shelves lasted through moving house without damage.

Hardware Makes or Breaks Shelf Strength

Not all shelf pins or brackets suit MDF. Hardware designed for other materials may not anchor well in MDF's fiber core. I once reused metal pins from an older solid wood bookcase and watched the shelves sink. Shelf hardware that is rated for MDF gives firm support and resists pulling out.

If you are buying hardware, check if the packaging mentions suitability for MDF. Reinforced brackets or pins with deeper seating work best. This swap eliminated shifting and rattling in my own shelves.

Sealing Edges Protects Against Moisture

You might think controlled indoor conditions are enough. However, even a little kitchen or bathroom humidity can swell unsealed MDF edges, causing them to fail. Professionals always seal every edge—even if unseen after installation.

Sealing methods include:

- Applying wood primer or varnish to all edges.

- Using factory-sealed prefinished MDF when possible.

- Paying special attention to cut edges from trimming or joinery.

After I started sealing every cut surface, I never saw swelling or edge cracking return.

Summary Table: Four Key Professional MDF Shelf Practices

| Professional Practice | How It Works |

|---|---|

| Shorter spans | Prevents mid-shelf sagging |

| Solid wood edge lipping | Boosts edge strength and lifespan |

| MDF-rated shelf hardware | Ensures reliable, durable support |

| Sealed shelf edges | Blocks moisture, prevents swelling and damage |

By following these proven practices, anyone can achieve long-lasting, professional-quality MDF bookshelf installations. These methods prevent common failures and make a clear difference in durability and appearance.

Limiting unsupported span is essential for preventing sagging in MDF bookshelves.True

Restricting the span reduces the weight distribution issues that cause bending in MDF shelves, enhancing their durability.

MDF bookshelves are immune to moisture damage, regardless of indoor humidity.False

MDF edges can swell if unsealed, making them susceptible to moisture damage, especially in humid environments.

7. How Do Top Brands Use MDF for Innovative Storage?

Struggling to find affordable storage that looks stylish and lasts? Cost or design usually wins over durability. MDF acts as a solution for projects requiring strength, finish, and value.

MDF is prized by top brands for combining a smooth finish with strength, making it ideal for stylish, durable storage systems found in homes, libraries, and professional environments worldwide.

Why Is MDF the Choice for Iconic Shelving Systems?

Many people recognize IKEA’s KALLAX and BILLY shelves. These shelving systems are familiar globally. They use MDF for a reason. MDF, or Medium Density Fiberboard, offers a paint-friendly surface. It also provides enough strength for daily use. The boards are affordable. They keep costs low for both makers and buyers. At the same time, they look good in modern homes. That is because MDF takes paint well. Surfaces look smooth and stay that way over time. There is no obvious grain or splintering. For large production, MDF ensures each piece matches. This creates the clean, modular look customers expect.

MDF in Precise Custom Millwork: Libraries and Offices

Custom millwork in formal spaces, like libraries or architect offices, often calls for materials with specific strengths. Here, MR-MDF (Moisture Resistant MDF20) stands out. It resists modest moisture. It can be shaped with tight tolerances. This is important in built-in shelving, cabinet doors, and wall panels. Millworkers prefer MDF because every cut edge stays smooth and uniform. When painted, shelves appear seamless, without the joints or wood grain lines you often see in natural wood. This makes the shelves and cases look like they are built in, not tacked on.

The benefits include:

| Feature | Why It Matters | Impact in Use |

|---|---|---|

| Smooth surface | Easier painting | Higher visual quality |

| High density | Stronger shelves | Safely holds more books or files |

| Moisture resistance | Less swelling disease | Holds up in humid rooms |

| Consistent edge quality | Precise joins | Tighter, durable fits |

School and Office Environments: Balancing Durability and Cost

Schools and offices need shelving and built-ins that survive daily bumps. They do not want to spend extra money every year on repairs. MDF offers a good balance. It is tough enough for moderate loads, such as books, supplies, or folders. The structure resists dings and dents better than cheaper particleboard. It is also less likely to warp than solid wood planks. Finishing the surface with paint seals the MDF. This prevents stains and makes cleanup easier.

In my own experience designing storage for a community center, I observed that MDF built-ins21 stayed cleaner and more intact than plywood units nearby. Users could stack boxes or lean against the shelving without leaving lasting marks. The cost per unit was lower, which allowed the project to add more storage within the same budget.

MDF’s Role in Affordable, Lasting Design

MDF remains a hidden hero in many projects. Its finishability, strength, and low price help top brands like IKEA deliver products that satisfy a wide range of people. Whether in your living room, a professional library, or a crowded classroom, MDF-backed storage offers visual appeal, consistent quality, and value. This combination makes it a preferred material where appearance, performance, and budget must align.

MDF is valued for its smooth finish and strength, making it suitable for stylish storage solutions.True

MDF provides a paint-friendly surface that looks good and is durable, which is why top brands use it for storage.

MDF is more likely to warp than solid wood planks.False

MDF is actually less likely to warp compared to solid wood due to its engineered composition and moisture-resistant properties.

8. Which Material Wins for Bookcases: MDF, Plywood or Solid Wood?

Are you unsure which material to choose for sturdy, stylish bookcases? Many homeowners find it hard to decide. Learn what really matters and how to get long-lasting results.

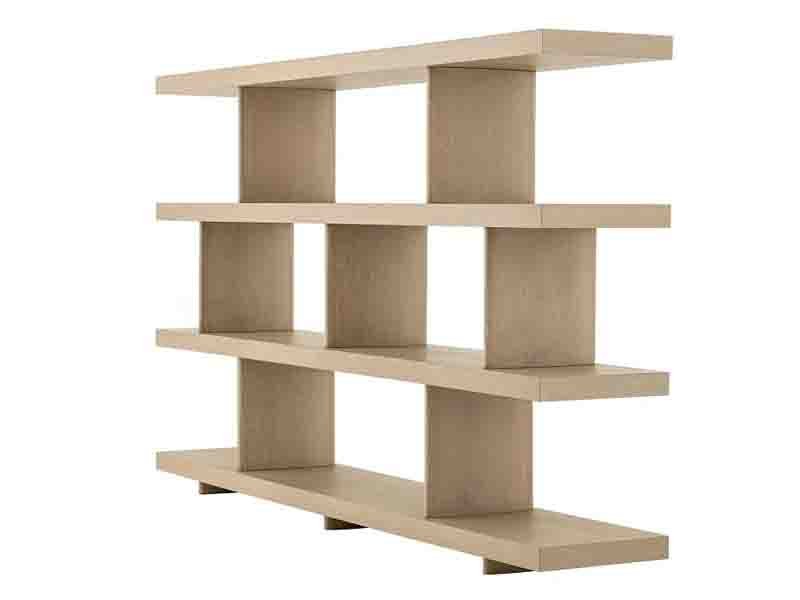

For bookcases, MDF is best for painted finishes, plywood is stronger for heavy or long shelves, and solid wood excels in traditional styles or if exposed grain is desired.

Understanding MDF, Plywood, and Solid Wood in Bookcase Construction

I have built and refinished many bookcases over the years. Each time, the choice of material made a big difference in how the project turned out. Let me break down how MDF, plywood22, and solid Wood23 each fit different design and functional needs for bookcases.

How MDF Stands Out

MDF, or Medium-Density Fiberboard, is engineered from wood fibers and resin. When I want smooth, modern-looking bookcases that need painting, MDF is my first pick. The material is dense, heavy, and has a surface free of grain, so paint lays down evenly with no texture or blotchy spots. In my experience, it is easier to cut clean edges in MDF than in plywood or solid wood, making custom built-ins simpler.

However, MDF has weak points. If I make a long shelf from MDF and load it with heavy books, the shelf may sag over time. It also does not hold screws as strongly as plywood or solid wood. When it is used for project parts like shelves that face stress, MDF usually needs extra support such as shelf pins or a solid back.

Where Plywood Excels

Plywood is made by layering wood veneers in alternating grain directions. For me, plywood is the choice when I want a bookcase that carries heavy stacks of books and needs to be wide or tall. Plywood resists bending much better than MDF, and it holds screws well. That gives it a clear advantage for long shelves or units that need to be moved or reassembled. Its surface may show some wood grain or knots unless I use veneer-grade panels, so it is often left with a clear finish or painted with prep.

Solid Wood: For Heirlooms and Unique Looks

I always admire solid wood for its beauty and traditional feel. Solid wood shows the natural grain, and when finished with oil or varnish, it can become a showpiece in a home. For a custom, heirloom bookcase or when the look of real wood matters, solid wood wins. But it is not for every budget. Compared to MDF and plywood, solid wood costs more by the board foot. It also can expand and contract with humidity, so careful joinery is needed to prevent warping or cracking over time.

Here is a quick comparison of the main factors:

| Material | Surface Finish | Strength for Shelves | Screw Holding | Cost | Aesthetic |

|---|---|---|---|---|---|

| MDF | Very smooth, paintable | Weak in long spans | Moderate | Low | Best for painted looks |

| Plywood | Some grain, paintable | Very strong | Strong | Moderate | Accepts clear or painted |

| Solid Wood | Natural grain | Very strong | Strong | High | Best for exposed grain |

How to Choose the Best Material

I always begin by asking myself what will matter most for this bookcase. If I will paint it to match wall color, or if budget is tight, MDF is hard to beat. If I need deep, sturdy shelves for a home library, plywood is my material. For a bookcase that is meant to last for generations or become a design focal point, solid wood earns its reputation—if I am ready to invest. Each project and space calls for its own answer. When I line up the pros and cons this way, I always land on the right material for my needs.

MDF is the best choice for painted finishes in bookcase construction.True

MDF has a smooth surface that allows for an even application of paint, making it ideal for painted bookcases.

Plywood is the best material for painted finishes on bookcases.False

Plywood's surface typically shows wood grain and knots, making it less suitable for a smooth painted finish compared to MDF.

9. Is MDF the Sustainable Choice for Healthy Indoor Bookshelves?

Many worry about indoor air quality and sustainability. Ignoring material choices can lead to harmful air and missed green goals. Opting for eco-friendly MDF panels24 solves these concerns.

MDF can be sustainable and low-emission if you choose panels with recycled fiber and certified low formaldehyde levels. This makes it suitable for bookshelves, particularly in sensitive environments like homes, schools, and medical offices.

What Makes MDF an Environmentally Responsible Option?

Sustainability matters in every construction decision. MDF, or medium-density fiberboard, often gets attention for its value and versatile use. Now, it is also seeing major advancements in environmental performance. Many MDF panels now use recycled or post-industrial fiber25. This innovation diverts waste from the landfill and helps conserve natural resources.

The table below summarizes key sustainability features of modern MDF:

| Feature | Sustainability Benefit |

|---|---|

| Recycled fiber content | Reduces waste, saves natural resources |

| Low-emission grades | Improves indoor air quality |

| LEED support | Qualifies for green building certification |

| Consistent quality | Minimizes material waste in production |

This table highlights how choosing MDF is about more than just cost. It is about active resource conservation. I have worked with MDF in education settings. I have seen the difference that low-formaldehyde, recycled content panels26 can make. There is noticeably cleaner air, and awareness of health grows.

Why Do Emissions Matter for Bookshelves?

Bookshelves live in our daily environments. Books can absorb and release chemicals over time. Children and people with sensitivities often spend hours near these shelves. If you use standard MDF, airborne formaldehyde release may become a concern. Long exposure can trigger headaches or allergies in some cases.

Opting for E1 or E0 grade MDF27, with formaldehyde emissions below 0.065 mg/m³, changes the equation. These grades release less harmful gases. Schools, hospitals, and homes especially benefit from materials that help keep air clean. This satisfies both health and regulatory demands.

How Does Choosing Sustainable MDF Impact Certification?

Green building standards are now at the forefront of many projects. MDF panels with recycled fiber content and low emissions qualify for programs like LEED (Leadership in Energy and Environmental Design)28. Selecting the right MDF supports these certification goals. It enhances resale value and aligns with responsible design principles.

Is Sustainable MDF Practical for All Projects?

Yes. Modern MDF is affordable and easy to finish. Green versions are available from most suppliers. Using sustainable MDF does not involve compromise. Instead, it creates new possibilities—safer, greener interiors and improved credentials for almost any application, especially shelving.

Choosing wisely when building bookshelves can protect indoor air and help the planet. Sustainable MDF shows that small material changes can make a big difference in daily life and long-term impact.

Eco-friendly MDF panels can improve indoor air quality.True

MDF panels with recycled fiber and low formaldehyde levels are designed to release fewer harmful chemicals, enhancing indoor air quality.

Standard MDF panels have lower formaldehyde emissions than E0 grade panels.False

Standard MDF typically has higher formaldehyde emissions than E0 grade MDF, which has emissions below 0.065 mg/m³, making E0 the safer option.

Conclusion

MDF is ideal for strong, affordable bookshelves in light to moderate load scenarios, offering aesthetic versatility and sustainability without compromising structural integrity.

-

Understanding moisture's impact on MDF can help you protect your investment and ensure longevity in your bookshelves. ↩

-

Learn about face frames and their role in enhancing the strength and aesthetics of bookshelves, crucial for DIY projects. ↩

-

Learn effective strategies to prevent sagging or warped shelves, ensuring your items remain safe and organized. ↩

-

Explore the advantages of MDF for shelving to ensure durability and stability in your home or office. ↩

-

Discover the optimal shelf thickness for MDF to maintain strength and prevent sagging, enhancing your shelving solutions. ↩

-

Discover the best materials suited for climate-controlled environments to enhance your interior design. ↩

-

Discover techniques and tips for achieving flawless results in woodworking, enhancing your project outcomes significantly. ↩

-

Learn techniques for achieving a stunning high-gloss finish on MDF, ensuring your projects look professional and polished. ↩

-

Learn about key factors to consider when purchasing bookshelves to ensure durability and value for your money. ↩

-

Discover why particleboard may not be the best choice for furniture compared to MDF, especially in terms of strength and durability. ↩

-

Explore this link to understand how edge-banding and laminates enhance furniture durability and aesthetics, making them essential in modern design. ↩

-

Discover how the ease of machining MDF improves production speed and quality, crucial for manufacturers aiming for efficiency. ↩

-

Learn about the balance of affordability and durability in furniture, ensuring you make informed choices for long-lasting pieces. ↩

-

Understanding this strength can help you choose the right MDF for your projects, ensuring durability and performance. ↩

-

Learn about MR-MDF's benefits to protect your projects from moisture damage, especially in high-risk areas. ↩

-

Exploring MR-MDF can help you make informed choices for moisture-prone areas, ensuring longevity in your projects. ↩

-

Learning about edge sealing techniques can prevent moisture damage and extend the life of your MDF installations. ↩

-

Explore how 700mm spans can enhance shelf stability and prevent sagging, ensuring your books are well-supported. ↩

-

Learn about edge lipping and its role in reinforcing shelves, protecting against damage, and enhancing durability. ↩

-

Learn about the unique properties of Moisture Resistant MDF and its applications in custom millwork and shelving. ↩

-

Discover the best materials for built-ins that offer durability and cost efficiency, perfect for schools and offices. ↩

-

Discover why plywood is favored for heavy-duty bookcases, ensuring durability and strength for your storage needs. ↩

-

Learn about the unique benefits of solid wood, including aesthetics and longevity, to see if it's right for your project. ↩

-

Discover how eco-friendly MDF panels can enhance indoor air quality and support sustainability goals in construction. ↩

-

Explore the significance of using recycled fibers in construction materials for a greener future. ↩

-

Explore how these panels improve air quality and health, making them a smart choice for sustainable building. ↩

-

Understanding these grades can help you choose safer materials that reduce harmful emissions in your environment. ↩

-

Learn how LEED certification can enhance your project's sustainability and value through responsible material choices. ↩

Published: 2025-06-25