Factory Glance

Why Choose Us

Welcome to Our Factory

At Tri-Tiger, we believe in complete transparency and craftsmanship you can trust. When sourcing furniture, you need a reliable manufacturer that delivers quality, consistency, and efficiency. That’s why we invite you to take a closer look at our state-of-the-art factory, where raw materials are transformed into beautifully crafted furniture through precision engineering and skilled workmanship. See firsthand how we ensure durability, design excellence, and international quality standards at every stage of production.

Years of Export Excellence

Employees(Production & Sales)

Exported Countries

Customer Satisfaction Rate

Step-by-Step

Our Manufacturing Process

Step 1

Raw Material Selection & Storage

We source high-quality solid woods (Paulownia, Oak, Pine, Walnut, Beech, etc.) and engineered boards (MDF, Plywood, Particleboard). Each batch is moisture-tested to ensure stability and stored in a climate-controlled warehouse to prevent warping, cracking, or swelling. Before production, all materials undergo a grading process to separate premium-quality wood from lower-grade materials.

Step 2

Precision Cutting & CNC Machining

Each wood panel or board is precisely cut using high-speed saws and CNC routers to ensure accurate dimensions. Drilling, grooving, and slotting are performed using multi-axis CNC machines to create precise cutouts for components like joints, screws, and dowels. This stage guarantees millimeter-level accuracy and ensures each part is ready for seamless assembly.

Step 3

Component Shaping & Edge Processing

Once cut, components undergo edge banding, profiling, and sanding to remove sharp edges and create smooth surfaces. For solid wood parts, milling and contour shaping are performed to achieve specific design details such as curves, bevels, or chamfers. The result is uniform components with perfect fitment and enhanced aesthetics.

Step 4

Joinery & Assembly

Furniture pieces are assembled using advanced joinery techniques, including mortise-and-tenon, dowel, dovetail, and screw joinery, depending on the design. Structural reinforcements like corner blocks or metal fasteners are applied where necessary. This step ensures structural stability, precise alignment, and long-term durability.

Step 5

Surface Treatment & Finishing

Each piece is carefully sanded to achieve a smooth, defect-free surface before moving to finishing. Depending on customer specifications, we apply stains, paints, laminates, veneers, or UV-cured coatings. Finishing is done using automated spray booths and hand-applied techniques to ensure even coverage, color consistency, and long-lasting protection against wear, moisture, and UV exposure.

Step 6

Drying & Curing Process

Once coated, furniture pieces are transferred to temperature-controlled drying chambers to allow finishes to cure and bond properly. For painted or lacquered surfaces, UV or infrared curing technology is used to accelerate the hardening process. This step ensures that coatings are resistant to peeling, cracking, and discoloration over time.

Step 7

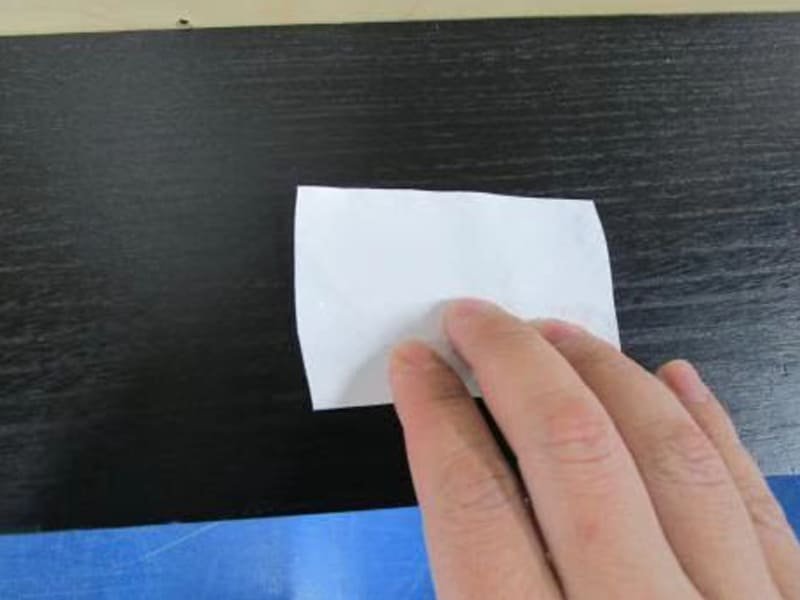

Quality Control & Final Inspection

Before packaging, each item undergoes a multi-stage quality inspection. We conduct structural integrity tests, surface smoothness checks, and color matching verification against approved samples. Durability tests, moisture resistance tests, and load-bearing tests are performed to ensure compliance with international safety and performance standards.

Step 8

Secure Packaging & Global Shipping

To prevent damage during transit, furniture is carefully wrapped with protective foam, edge protectors, and reinforced cartons. For flat-pack furniture, customized foam inserts and secure fastenings are used to minimize movement during shipping. Each package is drop-tested to meet international logistics requirements, ensuring products arrive in perfect condition to their final destination.

Seeing is believing

See Our Clients Visit Us

Nothing builds trust better than seeing where your products are made and meeting the team behind them. At Tri-Tigers, we welcome clients from around the world to visit our factory, inspect our production processes, and discuss business in person. Whether you are a wholesaler, retailer, or brand looking for a reliable furniture supplier, seeing our operations firsthand will give you complete confidence in our expertise and commitment to quality.

See Who Trusts Us

See the Quality for Yourself

On-Site Factory Inspection

We understand that transparency is key when choosing a reliable furniture supplier. That’s why we encourage you to conduct an on-site factory inspection at our facility. During your visit, you will have the opportunity to:

- Walk through our production lines, raw material storage areas, and finishing workshops.

- Observe our quality control procedures and see how we ensure consistency in every batch.

- Inspect product samples, material options, and surface finishes to verify craftsmanship and durability.

- Discuss your project in detail with our team to ensure your requirements are met.

We welcome all clients, from small retailers to large importers, to experience our production process firsthand and gain complete confidence in our capabilities.

Verified Quality & Compliance

Third-Party Audit

For clients who require an independent quality verification, we fully support third-party factory audits conducted by recognized global inspection agencies such as SGS, Intertek, TÜV, and Bureau Veritas.

- We allow third-party auditors to assess our facilities, production process, and quality management system.

- Our factory complies with international safety and environmental standards, ensuring your products meet regulatory requirements.

- We provide detailed compliance documentation, test reports, and certification records as needed for your market.

- Pre-shipment inspections can be arranged to verify quality, packaging integrity, and order accuracy before dispatch.

By allowing full access to independent verification, we guarantee authenticity, transparency, and reliability in every order we manufacture.