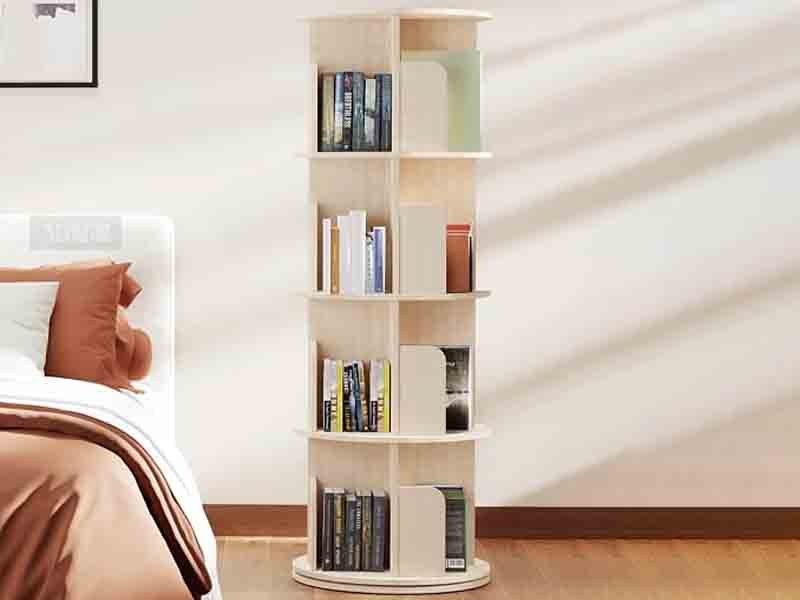

Featured image for Is Engineered Wood Good for Bookcases?

I once struggled with bookcases warping over time, leading to both aesthetic and structural issues. That's when I discovered engineered wood bookcases, which offer unparalleled stability and longevity, relieving these common frustrations.

Engineered wood bookcases are preferred by industry leaders due to their unmatched stability, strength, and design flexibility. Their resistance to warping, versatility in design, and sustainable sourcing add value, assuring longevity and reduced maintenance.

Exploring engineered wood, I found it solves many problems faced with solid wood. Its dimensional stability and reduced warping make it ideal for creating durable bookcases. The structural integrity over large spans ensures lower shelf sagging, and its enhanced machinability leads to more intricate designs. This material’s sustainable nature aligns with environmental goals, while its cost efficiency supports scalability for large productions. Additionally, engineered wood enhancements like fire and moisture resistance make it suitable for various settings. Understanding these advantages clarifies why industry preferences lean towards engineered solutions, promising a reliable installation and user experience.

1. Why Do Bookcases With Engineered Wood Last Longer?

Humidity warps ordinary bookcases1. Splitting shelves and wobbly panels happen fast. Engineered wood2 avoids these headaches. Here is how stable materials keep bookcases looking new.

Engineered wood bookcases last longer because their panels resist warping, splitting, and changes from humidity. This stability ensures shelves remain flat and square, helping them support weight and look good for years.

What Causes Bookcases to Warp?

I have seen many shelves sag and sides split open. Changes in air moisture cause solid wood to expand or contract. Winter makes the wood shrink. Summer humidity makes it swell. These movements break joints and twist panels. Every book collector knows the pain of watching favorite books lean or slide on warped shelves.

Engineered wood solves these age-old problems. Instead of a single block, many small fibers or thin layers of wood come together. They glue them tight using special adhesives. They press these mixtures hard with heat and pressure. The result is panels that barely move, even as seasons and rooms change.

Solid Wood vs. Engineered Wood

Here is how they compare:

| Feature | Solid Wood Panels | Engineered Wood Panels |

|---|---|---|

| Warping Risk | High | Minimal |

| Humidity Movement | Large | Very Small |

| Splitting | Often | Seldom |

| Surface Consistency | Varies | Always Smooth |

| Long-Term Shape | May Twist | Stays Flat |

Solid wood panels twist and crack often, even if trees looked flawless. Minor defects inside the wood show up years later. Glued engineered panels spread these forces out. Small flaws do not ruin the whole shelf.

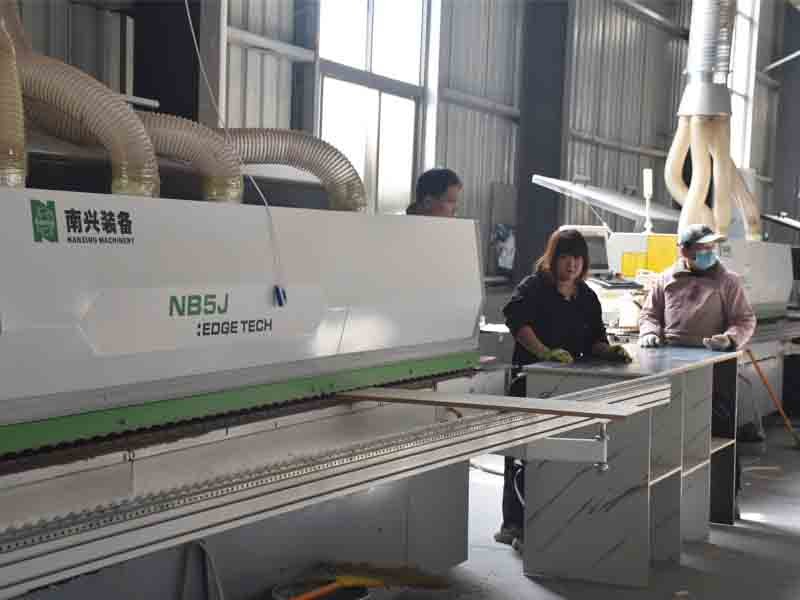

How Does Manufacturing Make Bookcases Stronger?

Modern panel plants bind wood at the fiber or veneer level. They mix chips, flakes, or fibers with strong glues. High heat and huge machines compress them into dense sheets. These sheets come out flat and stable. Weather does not make them bend. Sun or heaters do not pull them apart.

Panels like MDF (medium-density fiberboard) give a smooth finish for paint or laminate. Plywood adds many thin layers, crossing each grain for stability. Particleboard controls panel cost and gives decent performance. Each has its match depending on budget and look.

I notice that good bookcases always specify what panel type they use. If measurements are tight, MDF panels3 are my choice. When weight and cost matter, particleboard steps in. For those who want real-wood looks and grain, plywood wins, holding shape across years and moves.

Why Do Professionals Trust Engineered Wood?

Furniture makers get fewer defects when panels stay the same size. Fewer cracked joints and returns mean more happy customers. I remember assembling a solid wood bookcase, only to see sides bend inward the next winter. Engineered wood options did not have this issue. They cost less over time, since failure rates and repairs drop. Stability also lets designers use bigger shelves, knowing they will stay level.

In short, engineered wood bookcases resist the everyday wear that ruins others. Stable panels mean more reliable storage, fewer headaches, and book collections that sit safe and flat for years to come.

Engineered wood bookcases resist warping and splitting due to their stable materials.True

The structure of engineered wood helps it maintain its shape and resist damage from humidity, unlike solid wood.

Solid wood bookcases are less likely to warp than engineered wood bookcases.False

Solid wood bookcases are at a higher risk of warping and twisting due to changes in humidity compared to engineered wood.

2. What Makes Engineered Wood Best for Wide, Strong Bookcases?

Warped shelves and drooping panels can ruin even the most beautiful bookcases. The problem grows with wider spans. Engineered woods solve these issues with superior structural consistency.

Engineered wood like plywood and MDF offers greater shelf strength and less sagging over wide spans, ensuring bookcases remain stable and functional. Their uniform construction meets strict industry standards that solid wood often struggles with.

Why Wide Bookcases Demand More Than Solid Wood

Every book lover or designer faces a similar dilemma. When you need wide shelves or tall bookcase panels, will your materials bend or break down over time? I have seen sagging in shelves made of solid pine after only a year, even when they looked strong at first. It turns out, the secret to lasting stability lies in the material’s engineering. Shelves must handle heavy books, often over several feet of unsupported length. If the material flexes too much, you see warping, instability, or worse—panel failure.

That’s why many builders turn to plywood or MDF. These engineered woods are not just pressed together at random. Plywood uses cross-grain layers. Each layer runs at right angles to the last, spreading the load and making warping much less likely. High-quality MDF is made of fine wood fibers pressed tightly together. This creates uniform density, so there are no hidden weak spots.

How Engineered Wood Controls Shelf Deflection

Industry standards often specify a maximum deflection: 1/180th of the shelf’s span when fully loaded. What does that look like in practice? Here’s a simple table:

| Shelf Span (inches) | Max Allowed Deflection (inches) | Typical Plywood Deflection | Typical MDF Deflection | Solid Wood Deflection |

|---|---|---|---|---|

| 30 | 0.17 | 0.10 | 0.13 | 0.20 |

| 36 | 0.20 | 0.14 | 0.17 | 0.25 |

| 48 | 0.27 | 0.22 | 0.25 | 0.35 |

These numbers show why I trust engineered wood for long shelves. Both plywood and MDF4 stay safely below the industry maximum, even with heavier loads. Solid wood, while beautiful, shows much more movement because of natural grain variability and the risk of hidden defects.

Making the Right Material Choice

For large bookcases, strength is not just about having thick panels. Reliable load-bearing requires consistent performance across the entire shelf. Engineered products meet this need by design. For example, I built a custom six-foot shelving unit for a client using birch plywood. The top shelf never sagged, even under a full row of textbooks. When I tried the same with inexpensive pine boards, the central droop was obvious after a month.

Look for furniture or materials labeled with their construction. Ask about panel thickness and layered structure. Engineered wood panels over ¾ inch thick often surpass most solid woods for stiffness and resistance to warping.

Engineered wood panels like plywood and MDF offer clear advantages when building large bookcases. With industry standards in mind, they consistently outperform natural lumber for wide spans and heavy loads. This means more dependable, longer-lasting storage and less frustration for anyone who needs robust shelving.

Engineered wood products like plywood and MDF have superior strength and less sagging for wide shelves.True

Engineered woods are designed with consistent structural properties, making them better suited for handling heavy loads over wide spans without sagging.

Solid wood has better load-bearing capacity than engineered wood for wide bookcases.False

Engineered wood, like plywood and MDF, is specifically engineered to handle heavy loads and resist warping, outperforming solid wood in stability and support over long spans.

3. How Does Engineered Wood Boost Bookcase Design Flexibility?

Bookcase designers struggle with traditional wood’s limits. Uneven grain and tough finishes restrict creativity. Engineered wood changes things. Precise machining, smooth surfaces, and stable structure unlock innovative designs that meet mass production demands.

Engineered wood’s uniform structure lets bookcase makers create custom, intricate shapes and clean finishes that are hard to do with natural wood. CNC machining enables repeatable, precise details for flexible and scalable designs.

What Sets Engineered Wood Apart in Precision Crafting?

Traditional wood frustrates builders. Each plank acts a bit different. One board may warp or chip, and sandpaper fights hidden grain. Engineered wood solves these daily headaches. I have worked on both kinds. Engineered panels always feel the same in the workshop. Joints are tight. Angles stay true. I know what to expect when the saw goes through.

Here is why it matters:

- With engineered wood, every board acts the same.

- I can set the machine once and cut a hundred pieces. Each will fit together with no gaps.

- Bookshelves need strong joints, hidden screws, and neat corners. CNC routers5 cut grooves and recesses for hidden fasteners. Every shelf mount sits flush.

- Tools do more than cut straight lines. Routers carve out curves, relief details, and special edges. I can offer customers custom profiles without hand carving.

- The even, sealed surface means the paint or veneer always looks smooth. No knots, cracks, or weird colors show through.

Applications in Detail: Machinability and Surface Perfection

In bookcase production, precision matters. Mass production needs consistency. Modern factories use CNC routers to cut panels, drill dowel holes, and make slots for brackets. Engineered wood handles this well.

| Feature | Engineered Wood | Solid Wood |

|---|---|---|

| Surface | Very smooth, uniform | Can be rough, uneven |

| Machinability | Easy, precise cuts | Can chip or split |

| Joinery | Strong, neat joints | Prone to gaps |

| Customization | Highly flexible | Limited by grain |

| Finish Quality | Consistent look | Visible grain marks |

Factories run faster with engineered panels6. Each time I made a run of bookcases with solid wood, there were always a few that had to be fixed or scrapped because parts did not fit. With engineered boards, waste drops. Brackets, adjustable shelves, and modular pieces fit every piece.

The Designer’s Perspective: Freedoms Gained

Designers appreciate what this material offers. You do not see grain patterns showing through a white or colored finish. If a customer asks for a precise shade, the laminate goes on flat and true. Concealed lighting, curved edges, or flush-mounted hardware all become easier. When a project calls for hundreds of identical pieces—such as in schools or offices—engineered wood ensures that every bookcase matches.

Finishing Effects: Aesthetic Variety

The surface is ready for high-end veneers, trendy laminates, or top-tier paints. If the style calls for a minimalist matte look or a glossy modern sheen, the substrate does not get in the way. Natural wood often limits the choice or makes results unpredictable. With engineered panels, designers fulfill the look clients want.

The Takeaway

Engineered wood offers a reliable base for precise, repeatable, and creative bookcase manufacturing. Its uniformity means makers can count on each piece fitting and looking as planned, every time. This material gives both builders and designers more freedom to deliver quality and style efficiently.

Engineered wood allows for consistent and precise crafting in bookcase design.True

Its uniform structure and properties ensure that every piece behaves the same, facilitating exact measurements and fit.

Traditional wood offers more versatility in design compared to engineered wood.False

Engineered wood's stability and uniformity actually provide greater design flexibility, unlike traditional wood which can warp and has inconsistent grain.

4. How Do Eco Certifications Raise the Value of Engineered Wood?

Many want wood furniture that is both stylish and responsible. But how can you tell if your engineered wood supports the environment? Eco certifications make the difference.

Eco certifications like FSC and CARB show that engineered wood comes from responsible sources and meets strict standards for emissions and sustainability. These certifications help you pick products that protect forests and indoor air.

Understanding Sustainable Material Sourcing

Sustainable material sourcing focuses on how companies select and harvest raw materials. For engineered wood, it is about using fast-growing trees, recycled fibers, or by-products. This approach is very different from using only old hardwoods. I have seen how much waste can come from the furniture industry. Using leftovers or quick-growing species helps cut that down. It means fewer old trees cut, and more value from what is already harvested.

Supply chains that support sustainability also use careful tracking. Many now use blockchain or detailed records. This proves that materials come from where they claim. It is not just about the wood itself. The whole process counts. Even glue and energy can be part of a responsible system.

Why Certifications Like FSC and CARB Matter

Two main eco certifications7 lead in the world of engineered wood. They are the Forest Stewardship Council (FSC) and the California Air Resources Board (CARB). Both ask companies to meet high standards.

Table: Quick Guide to FSC and CARB Certifications

| Certification | Focus | What It Means for You |

|---|---|---|

| FSC | Forest management | Wood comes from forests cared for long-term |

| CARB | Indoor air quality, emissions | Panels meet strict limits on formaldehyde |

FSC certification8 tells me the wood is not just being cut and forgotten. It is cared for with a longer view. Forests stay healthy for future generations. Companies have to meet social and environmental rules.

CARB is about health inside homes and offices. Engineered woods can sometimes release gases, especially formaldehyde. CARB limits9 that. When I see this label, I know someone checked that the product is safe for indoor use.

Adapting to Modern Demands and Green Building Standards

More buyers care about green standards. That includes big institutions and home designers. Certifications help boost the value of engineered wood. They make it easier to include bookcases and panels in projects aiming to meet environmental standards.

In my work, I have watched certification shift from a “nice to have” to a must. When a product carries both FSC and CARB badges, it stands out against those with nothing. It can go into buildings targeting LEED or WELL standards. This is a signal to future-focused clients and tenants.

Why Eco Certification Builds Trust

A label from FSC or CARB is more than a logo. It stands for years of effort from forest to finished panel. Many times, I have chosen certified wood above cheaper alternatives. It feels good to know I am helping protect forests and reduce pollution, even in a small way. Demand for certified panels will keep growing, as people seek trust and transparency in every purchase.

Choosing engineered wood with strong certifications drives demand for responsible supply. It sends a message up the chain. Over time, more forests will be managed well, and indoor spaces will be healthier, thanks to these choices.

Eco certifications like FSC and CARB indicate responsible sourcing and sustainability standards for engineered wood.True

FSC and CARB ensure that engineered wood meets environmental standards and comes from responsible sources.

Eco certifications allow any type of wood, regardless of its sourcing, to be marketed as environmentally friendly.False

Eco certifications only apply to wood that meets specific environmental and sourcing standards, not any type of wood.

5. How Does Engineered Wood Boost Bookcase Production Efficiency?

Rising costs make affordable quality hard to achieve. High waste and slow production add stress. Engineered wood offers a solution for scalable, cost-effective bookcase lines without losing value.

Engineered wood boosts bookcase production efficiency by lowering costs and reducing waste. Standardized panel sizes streamline manufacturing, improve yield, and enable faster, scalable production while maintaining competitive pricing and reliable performance.

Why Engineered Wood Matters for Cost and Scale

When I look for ways to make production more efficient, material costs stand out. Engineered wood uses less expensive resources than solid wood. The panels come in standard sizes, like 4 feet by 8 feet or 5 feet by 12 feet. This standardization helps cut down on waste. Every sheet yields more usable parts. It is easy to plan each cut.

Lower raw material costs mean the base expense of each bookcase drops. Processing costs are also lower. Engineered wood can be shaped quickly and smoothly. Machines can handle it without constant adjustments. This speeds up production time and cuts labor costs.

I have seen how using standardized engineered panels lets you scale production. It is easier to meet big orders without missing deadlines. When you have a large set of bookcases to make, you can calculate exactly how many panels are needed. There are fewer surprises and less unused scrap.

Standardized Panels10 Enable Smart Manufacturing

Uniform panel sizes are key to just-in-time production methods. I can order a batch, receive it ready-to-go, and fit it right into the cutting plan. The yield per sheet is predictable. This lets me fulfill orders quicker. If one bookcase design works for a 4’x8’ panel, I know every time what I get from each sheet.

| Panel Type | Standard Size | Yield per Panel | Typical Applications |

|---|---|---|---|

| Engineered MDF | 4’x8’, 5’x12’ | High | Bookcases, shelving |

| Solid Hardwood | Varies | Lower | High-end furniture |

| Particle board | 4’x8’ | High | Entry-level bookcases |

I used to struggle with variable wood dimensions. Solid wood boards can have knots or different widths. Engineered wood gives uniformity. This makes it possible to automate more steps with less error. Machines run with fewer interruptions.

Competitive Advantage Through Cost and Speed

Profit margins improve when you spend less on each piece and sell at a competitive price. Buyers want good performance but often decide on price. Engineered wood blends both needs. The materials pass strength and durability standards for bookcases. Customers get reliable storage; I can keep prices in check.

Faster order fulfillment becomes possible. When demand spikes, I do not worry about delays. Materials arrive in sheets I already expect. Cut plans adapt fast. Production lines adjust to large runs or custom requests with the same efficiency.

Engineered wood gives me the flexibility to grow. Instead of limiting production to the quirks of solid wood supplies, I have a stable foundation. This reliability helps expand to new markets or scale up operations—all while controlling costs.

In my experience, engineered wood turns the challenge of cost and scale into an advantage. It keeps production lines11 moving and supports quality bookcases in every order.

Engineered wood reduces production costs and waste effectively.True

Engineered wood is made from less expensive materials and comes in standardized sizes, which helps lower raw material costs and minimizes waste during production.

Engineered wood is more expensive and less efficient than solid wood.False

Engineered wood is generally less expensive and provides more efficient production processes compared to solid wood, making it a preferred choice for scalable manufacturing.

6. How Do Engineered Wood Bookcases Offer Superior Safety Features?

Bookcases can fail when exposed to fire, pests, or moisture. This creates hazards and financial loss. Choosing engineered wood with enhancements is the solution for peace of mind.

Engineered wood bookcases deliver advanced fire, pest, and moisture resistance thanks to special additives and treatments. These features allow bookcases to meet strict safety codes in demanding settings, outperforming traditional solid wood options.

How Engineered Wood Resists Fire, Pests, and Mold

Engineered wood is more than just pressed chips and adhesive. When constructed for higher performance, manufacturers add specific chemicals or resins. These additives do more than strengthen the wood—they actively defend against dangers that threaten both people and property.

I often think of the difference I saw in a school library renovation. The original hardwood bookcases, though beautiful, failed strict fire and termite codes. Switching to fire-rated, treated MDF solved both issues. I saw firsthand how students now worked around shelving that met all local safety rules—no compromises required.

Fire Resistance: Meeting the Highest Standards

Some grades of MDF and particleboard include fire-retardant resins12. These panels are often tested to comply with the ASTM E84 standard, which measures how quickly fire and smoke spread on a material’s surface. Meeting this code is not optional in schools and hospitals.

| Panel Type | Fire Rating (ASTM E84) | Typical Uses |

|---|---|---|

| Standard MDF | Moderate | Homes, light offices |

| Fire-Rated MDF | Low Flame Spread | Schools, hospitals |

| Standard Particleboard | Moderate | General furniture |

| Fire-Rated Particleboard | Low Flame Spread | Public spaces |

Fire-rated options buy time in emergencies. The material slows ignition and gives people key extra minutes to escape. I watched a fire drill once where maintenance explained how their new engineered shelves actually delayed smoke build-up. Knowing this made everyone feel safer.

Preventing Damage by Insects and Mold

It is not just fire to worry about. Insects like termites can eat wood furniture, and high humidity brings mold that ruins books and is bad for health. Engineered panels used in demanding environments get anti-fungal and insecticidal additives.

This matters in settings like clinics and libraries, where collections and building health must stay protected year-round. Solid wood needs heavy chemical treatments to keep pests and mold away, but these can sometimes smell or fade over time. By contrast, engineered panels13 come pre-treated, and the protection is built in—not just on the surface.

Moisture Defense for Long-Lasting Value

Most engineered wood intended for sensitive environments is also moisture-sealed14. This keeps shelves from swelling or warping. The process stops books from slipping or tipping due to misshapen shelves after a rainy season or cleaning mishap.

From what I have seen, this long-term durability means fewer replacements and better return on investment for the buyer—be it a headmaster, medical director, or facilities manager.

Engineered wood bookcases specified for enhanced resistance bring tangible safety and health benefits. These products pass rigorous fire, pest, and water exposure tests. They deliver peace of mind for any institution setting high safety standards.

Engineered wood bookcases enhance safety by resisting fire, pests, and moisture.True

These bookcases are treated with special additives that improve their fire, pest, and moisture resistance, making them safer than traditional solid wood options.

Engineered wood bookcases have no fire resistance capabilities.False

Engineered wood bookcases often include fire-retardant resins, meeting strict safety codes and providing fire resistance, which traditional wood options lack.

7. Why Are Uniform Surfaces Essential for Modern Bookcases?

Invisible inconsistencies ruin precision finishes. Project specs grow stricter. Engineered bookcases with flawless surfaces solve both problems—offering new potential for coatings and durability in modern spaces.

Uniform surfaces make engineered bookcases perfect for advanced finishing like laminates, melamine, and UV-cured coatings. Their flaw-free base allows scratch-resistant, antibacterial, and designer treatments that meet strict commercial demands for both style and function.

Engineered Uniformity: The Secret to Superior Surface Treatments

My first experience with engineered bookcases was during a university library renovation. The architect insisted on a “zero-variation look” for all shelving. Natural hardwood could not provide this. Even its best pieces had unpredictable grain and color mismatches. We needed a better answer. Engineered wood offered a surface like a blank canvas. Each bookcase looked identical. It made surface treatments15 easier—and more successful.

This engineered uniformity matters. Commercial spaces such as libraries, offices, and public institutions need more than simple storage. They must withstand heavy use. People want lasting finishes without wear, color fading, or germs. Surfaces as consistent as possible are essential when suppliers apply high-pressure laminates (HPL), melamine, or modern UV-cured coatings.

How Uniformity Enables Advanced Surface Technologies

Here’s why the absence of wood grain variation matters:

| Surface Factor | Benefit for Bookcases | Commercial Advantage |

|---|---|---|

| No grain variation | Seamless finish consistency | Easier to match project specs |

| Even density | Reliable adhesion of coatings | Strong, lasting protection |

| Fewer weak spots | Enhanced scratch resistance | Lower maintenance cost |

| Smooth appearance | Modern aesthetic options | Design flexibility |

Uniform panels make high-pressure laminates stick better and look cleaner. Laminates need a perfectly smooth base so seams do not stand out. Melamine coatings also require this kind of consistency. Without it, coatings can bubble or separate. I saw this mistake in a previous project when an untested veneer caused costly coating failures—and weeks of delay.

The rise of UV-cured coatings16 has made engineered uniformity17 even more important. These treatments rely on meticulous application and exact surface chemistry. Inconsistent grain or porous spots can ruin a UV finish. Bookcases made from uniform panel boards allow these coatings to cure evenly. This delivers the beautiful, resilient finishes modern clients want.

Meeting Rigorous Project Expectations

Commercial designers often specify strict criteria:

- Scratch resistance for daily use

- Antibacterial or easy-clean surfaces

- Color consistency for institutional branding

- Resistance to stains, heat, and moisture

Uniform engineered panels meet all these needs. Custom coatings do not react unpredictably. Designs match exactly from one bookcase to the next. During a recent hospital furniture project, bookcases had to pass cleaning tests with harsh chemicals. The engineered surfaces passed—natural wood could not.

The Shift Toward Engineered Solutions

There is a growing trend. Library and office specifiers now request engineered bookcases for high-profile projects. Students, workers, and staff touch the surfaces thousands of times each year. Small flaws multiply into big problems over time. Bookcases with precision-made, flaw-free surfaces solve this challenge.

Uniformity does not just look clean—it enables technology. Antibacterial surfaces installed in clinics, or fingerprint-resistant finishes in shared offices, rely on having no wood grain surprises beneath the surface. Engineered bookcases make this possible.

I have seen many clients return to this solution after failed attempts with natural wood. Once they see the results—longer use life, beautiful finishes, and easier cleaning—they rarely go back.

Uniform surface technology is not just a trend. It is now a standard in modern library and institutional design. Every bookcase benefits when the base is perfect for advanced finishing.

Uniform surfaces in engineered bookcases enhance the effectiveness of advanced coatings.True

Uniform surfaces ensure reliable adhesion and prevent issues such as bubbling, making coatings like laminates and UV finishes more effective.

Natural wood surfaces provide better adhesion for advanced coatings than engineered surfaces.False

Natural wood surfaces have grain variations that can hinder adhesion, whereas engineered surfaces are specifically designed to be uniform and smooth for optimal coating application.

8. How Does Engineered Wood Ensure a Smooth Installation?

Unexpected problems during installation can slow projects and frustrate users. Stress mounts when parts misalign or panels warp. Engineered wood’s reliability offers a straightforward and consistent solution.

Engineered wood delivers consistent sizing, pre-drilled accuracy, and stable panels, making the installation process smooth and efficient while reducing errors, service calls, and client complaints. This leads to better experiences and satisfied end users.

The Benefits of Consistency in Engineered Wood

When I first managed a large bookcase installation, I was nervous. Would everything go together easily? Luckily, with engineered wood, every shelf supported my expectations. The pre-drilled holes met exactly where they should. The panels fit without effort. This was not luck, but the result of engineered wood’s manufacturing process18.

What Makes Engineered Wood Predictable?

Engineered wood starts in the factory, where each sheet is pressed and cut to strict tolerances. This means every panel has the same thickness and dimensions. Other wood types, like solid wood, may twist or bow. But engineered wood remains steady, even after shipping and storage.

When parts arrive, installers find:

| Feature | Engineered Wood | Other Materials |

|---|---|---|

| Dimensional Accuracy | High | Low-Medium |

| Pre-Drilling Quality | Consistent | Inconsistent |

| Panel Stability | Excellent | Variable |

| Common Assembly Issues | Rare | Frequent |

I saw this first-hand when our team set up units for a school library. Every pre-drilled hole lined up, every support locked in tight, and none of the panels rocked or tilted. After the job, there were no callbacks. The client was happy. This was no accident. This level of predictability19 happens because engineered wood is made with uniform layers of fiber or veneer, pressed with resins, and cut by machines held to the millimeter.

Impact on Service Calls and User Confidence

Inconsistent furniture pieces cause trouble. A shelf may wobble, or holes may be off-center. This leads to complaints and return visits. Engineered wood avoids those issues. When installers can trust every piece, the job finishes faster, and customers relax—knowing they won’t need repairs. This builds trust with buyers and makes people more likely to recommend the product.

Why Predictability Matters in Multi-Unit Installations

Large projects, such as outfitting student housing or offices, have strict deadlines. Products that arrive ready to assemble, with no surprises, let workers finish quicker. Fewer mistakes mean less time wasted. Procurements teams value these benefits. It helps your product stand out and earns repeat orders.

Conclusion: The Everyday Advantage

With engineered wood, the assembly process becomes routine rather than risky. Installers expect each piece to fit—because it does. This predictability reduces stress, lowers costs, and builds lasting satisfaction for organizations and users alike.

Engineered wood provides consistent sizing and pre-drilled accuracy for easier installation.True

The manufacturing process of engineered wood ensures uniformity in thickness and dimensions, which facilitates straightforward assembly without misalignment issues.

Engineered wood often warps and misaligns more than solid wood during installation.False

Unlike solid wood, engineered wood is designed to be stable and resistant to warping, significantly reducing installation problems related to misalignment and warping.

Conclusion

Industry leaders favor engineered wood bookcases for their stability, durability, sustainability, cost efficiency, and design versatility, ensuring high-quality products that meet modern demands.

-

Learn about the effects of humidity on bookcases and discover solutions to prevent warping and damage. ↩

-

Explore the advantages of engineered wood to understand how it can enhance the durability and stability of your bookcases. ↩

-

Learn about MDF panels, their properties, and why they are a popular choice for smooth finishes in furniture design. ↩

-

Discover how plywood and MDF stack up against each other in furniture making, focusing on performance, cost, and longevity. ↩

-

Learn how CNC routers revolutionize woodworking by ensuring accuracy and efficiency, crucial for modern furniture production. ↩

-

Explore this link to understand how engineered panels enhance efficiency and reduce waste in manufacturing processes. ↩

-

Learn about eco certifications to ensure your furniture choices are environmentally friendly and responsible. ↩

-

Explore this link to understand how FSC certification ensures sustainable forestry practices, benefiting both the environment and future generations. ↩

-

Learn about CARB limits and their role in ensuring safe indoor air quality, crucial for health in homes and offices. ↩

-

Learn about the advantages of standardized panels in streamlining production and minimizing waste. ↩

-

Discover strategies to optimize production lines for engineered wood, ensuring efficiency and cost-effectiveness. ↩

-

Learn how fire-retardant resins enhance safety in engineered wood, making it a smart choice for fire-prone areas. ↩

-

Explore how engineered panels enhance safety and durability in various environments, ensuring long-lasting protection. ↩

-

Learn about the advantages of moisture-sealed wood in preventing damage and maintaining structural integrity over time. ↩

-

Discover cutting-edge surface treatment technologies that enhance the performance and aesthetics of engineered wood products. ↩

-

Explore this link to understand how UV-cured coatings enhance durability and finish quality in engineered surfaces. ↩

-

Discover the significance of engineered uniformity in achieving consistent quality and performance in modern furniture. ↩

-

Learn about the manufacturing process to see how it contributes to the predictability and performance of engineered wood. ↩

-

Learn how predictability enhances efficiency and reduces errors in large-scale projects, ensuring timely completion. ↩

Published: 2025-07-23