MDF stability transforms how I appreciate furniture. I’ve watched as my wooden shelves warped and cracked, but with MDF, those issues disappeared, offering reliable beauty and function.

MDF stability is pivotal in modern furniture due to its dimensional integrity, precision machining capabilities, and compatibility with advanced finishes. This ensures long-lasting, visually appealing pieces that withstand climatic variations and frequent usage without warping.

Exploring MDF's significance in furniture reveals its unparalleled stability. It prevents swelling and warping, integral to maintaining aesthetics and operation. Precision cutting and resistance to deformation secure MDF’s place as the material of choice for contemporary brands seeking lasting, dynamic designs.

1. Why Does MDF Stay Flat While Wood Warps Over Time?

Moisture changes can ruin smooth panels and perfect edges. Warped or swollen surfaces look bad and make assembling furniture tough. MDF’s stability1 offers an easy fix to these headaches.

MDF stays flat because its fiberboard structure and resin prevent movement caused by moisture, unlike solid wood. This stability ensures panels maintain shape and integrity where even tiny changes could cause trouble.

The Science Behind MDF’s Dimensional Stability

I have seen furniture with solid wood panels lose its shape in one rainy season. Gaps grew. Joints stuck. The panels cupped. Each piece felt like a gamble. MDF changed things for me. Its engineered structure solved these issues.

Why Does Wood Move?

Wood is strong but complex. Its grain structure pulls water in and pushes it out. This happens across the grain, never evenly. So wood grows or shrinks as air changes.

When used for cabinet doors or desktops, this movement causes swelling at the edges, warping in the center, or cracking along joints. Assembly becomes tricky. Surfaces may stick or rattle. Paint can flake as wood swells. Repair is hard and costly.

MDF’s Secret: Engineered Consistency2

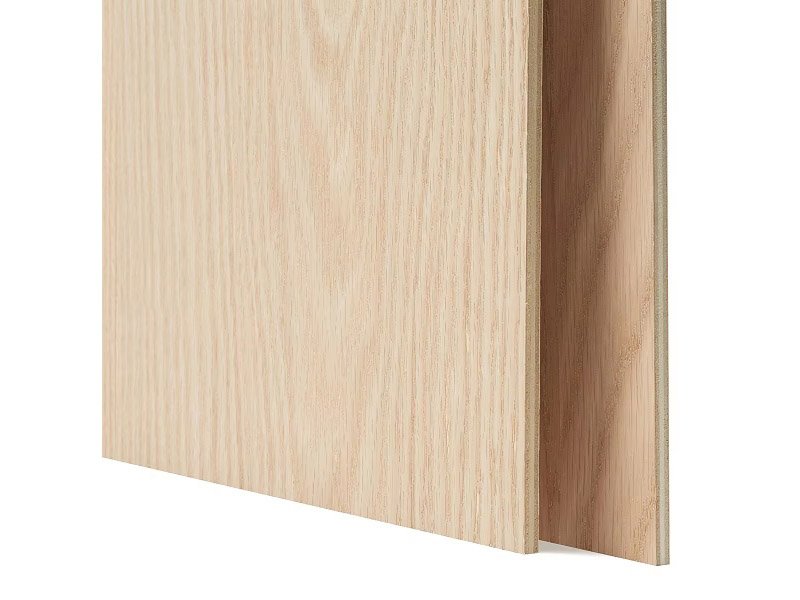

MDF is not cut from a log. Manufacturers break wood down into fibers. They mix them with resin and press them into sheets under heat.

Every part of the MDF panel is identical. There is no grain to move differently. Resin fills micro-gaps and wraps each fiber. This locks shape in place.

Here is how MDF and solid wood compare:

| Property | MDF | Solid Wood |

|---|---|---|

| Reaction to Humidity | Minimal change | Expands/contracts |

| Surface Flatness | Very stable | Can warp/cup |

| Panel Size Limits | Large, uniform panels | Limited, can deform |

| Common Uses | Cabinet doors, desk tops | Frames, carving |

The Impact on Manufacturing and Use

I now use MDF for almost every modern cabinet, especially for wide doors and sides. Measuring once saves work later. No more field fixes for doors that do not close.

Uniform thickness lets machines cut crisp edges and paint goes on evenly. As a result, time and waste are lower. For consumers, this means flat doors that never stick and surfaces that look new for years.

Where I Avoid MDF

Sometimes, I avoid using MDF in spots with direct water contact or where very high strength is needed along the edge. It is not indestructible. But for interior panels, nothing else has solved warping and swelling as well.

I recommend MDF when you want clean lines and lasting panel surfaces. Its dimensional stability3 makes it the first choice for reliable furniture, especially in changing climates. This one innovation—fiberboard with resin4—solves problems that have troubled furniture makers for centuries.

MDF maintains shape and dimensional stability better than solid wood.True

MDF's engineered fiberboard structure and resin prevent movement caused by moisture, ensuring it remains flat over time unlike solid wood.

Solid wood panels stay completely unchanged by moisture and do not warp.False

Solid wood is affected by moisture, leading to expansion, contraction, and potential warping, which MDF is specially designed to avoid.

2. How Does MDF Achieve Precision Furniture Tolerances?

Clean-lined furniture often disappoints when joints are loose or don’t align. Frustration grows as parts don’t fit. MDF’s structure solves these assembly challenges and enables perfect, consistent results.

MDF provides high-precision machining, allowing machinists to achieve tight tolerances of 0.1-0.2 mm. This stable, homogenous structure ensures flawless joints, easy part interchangeability, and smooth assembly, making it ideal for both standard and custom furniture applications.

Understanding Precision in Modern Furniture

Modern furniture is recognized by its clean lines. These creations demand joints and components that fit as intended. Achieving this precision relies on consistent raw material. MDF—medium-density fiberboard—addresses these strict needs. The core reason is its uniform, homogenous structure. Unlike natural wood, MDF avoids knots, rings, or unexpected density changes. Tools cut through the board with predictable resistance and produce consistent results. I have noticed, while working on custom cabinetry, that irregular hardwoods challenge even the most skilled craftspersons. In contrast, MDF’s evenness helps meet tight manufacturing tolerances.

Why Tight Tolerances Are Essential

Tolerances define how closely a finished part’s dimensions approach their target size. For furniture, this is crucial. Consider these problems:

- Slightly oversized panels push frames apart.

- Undersized shelves fall out.

- Misaligned profiles ruin a clean appearance.

Flat-pack furniture, often assembled by customers, must fit together without confusion or frustration. For producers, tight tolerances5 also mean fewer rejected parts and less rework.

How MDF Enables Superior Machining Accuracy

Machining accuracy depends on how the tool moves through the material. MDF offers:

- Uniform density across the panel.

- Resistance to chipping at the edges.

- Low internal stress, so panels remain flat.

These qualities enable routers, CNC machines, and saws to cut precisely and reliably. Furniture produced in batches can maintain tolerances to within 0.1-0.2 mm. That’s finer than the width of a human hair.

| Feature | MDF Performance | Solid Wood Performance |

|---|---|---|

| Density Uniformity | Very high | Variable |

| Machining Accuracy | 0.1-0.2 mm | 0.3-1.0 mm |

| Joint Reliability | Consistent | Inconsistent |

| Warp Resistance | Strong | Weak variable |

Real-World Impact for Furniture Design

Precision-made MDF parts6 deliver several concrete benefits. You get invisible joints that vanish under finishes, leading to the streamlined look many designers want. Assembly goes smoothly because all holes and dadoes line up. In large-scale production, part interchangeability is critical. Over my career, I have seen how a batch of MDF parts assembled by different workers results in uniform finished products. This is true both for flat-pack furniture kits and highly detailed bespoke work.

Detail Work and Creative Freedom

Designers use routers to cut decorative edge profiles. MDF supports intricate patterns—contours hold their shape with crisp edges. Clients often ask for subtle moldings or inlays. MDF provides a predictable base for these details because every panel acts the same during machining. Creativity expands when part compatibility is guaranteed.

Precision machining7 and MDF’s stable makeup allow furniture makers to push design boundaries. The result is furniture with seamless connections and consistently high quality, meeting both the expectations of users and the demands of modern design.

MDF allows for machining tolerances of 0.1-0.2 mm, ensuring high precision in furniture construction.True

The structure of MDF provides consistent density, enabling precise cutting and fitting of furniture components within tight tolerances.

MDF is made from solid wood and inherently has variable density.False

MDF is composed of wood fibers and resin, creating a uniform and homogenous structure, unlike solid wood which has variable density and can include knots and other imperfections.

3. Why Is MDF the Ideal Choice for Modern Surface Finishes?

Many finish techniques fail with unstable surfaces. Frustration and wasted material result. MDF offers a stable base, solving these finish failures and delivering uniform results every time.

MDF’s smooth, stable surface stops finish problems like cracking or delamination. It resists telegraphing and supports even, professional finishes for high-gloss lacquers, laminates, and vinyl wraps.

The Importance of Surface Stability in Modern Finishes

Some of the most popular furniture and cabinetry designs today depend on flawless finishes. These include high-gloss lacquers, seamless laminates, and intricate vinyl wraps. The final look depends not just on the skill of the finisher, but more on the substrate below. When I first tried spray finishing on a rough-surfaced material, I noticed bumps telegraphing through my paint. The result looked less than professional, and the finish soon cracked.

That is where MDF stands out. Its engineered surface is dense and ultra-smooth. Unlike plywood or particle board, MDF does not have voids, knots, or rough patches that show through after finishing. The table below shows how MDF compares to other common substrates:

| Substrate | Surface Smoothness | Susceptibility to Telegraphing | Finish Stability |

|---|---|---|---|

| MDF | Very High | Very Low | Excellent |

| Particle Board | Medium | Medium | Fair |

| Plywood | Low | High | Variable |

| Solid Lumber | Variable | Variable | Variable |

Common Problems with Unstable Substrates

I have seen paint crack, peel, or become cloudy over time when applied to unstable substrates8. Fluctuations in temperature and humidity cause these materials to expand or contract. The finish cannot keep up, so it splits or separates. Sometimes, the uneven backing can make even the best vinyl wrap look bubbled or misaligned. For clients who demand perfect results, this is unacceptable.

How MDF Resolves These Finish Issues

MDF’s composition is uniform from core to surface. It does not shift with changing temperatures or humidity nearly as much as natural wood or cheaper boards. When you spray lacquer or roll on laminate, MDF does not let ridges or dips spoil the final look. The stability also keeps paint or laminate bonded tightly, with little risk of future peeling.

For demanding applications such as kitchen cabinets or display furniture, this kind of reliability is essential. I have watched as teams move pre-fab panels from a workshop to a site with fluctuating conditions. MDF panels come out looking exactly as intended, with finishes still flawless.

For anyone focused on appearance and lasting performance, the choice of substrate matters as much as the finish itself. MDF’s stable, flawless surface9 makes it the first choice for all contemporary surface finishes, ensuring professional results and fewer costly re-dos.

MDF provides a stable base for high-quality surface finishes.True

MDF's smooth and uniform composition prevents issues like cracking or delamination, making it ideal for modern finishes.

MDF is prone to significant telegraphing, similar to plywood.False

MDF has very low susceptibility to telegraphing compared to plywood, making it a better choice for smooth finishes.

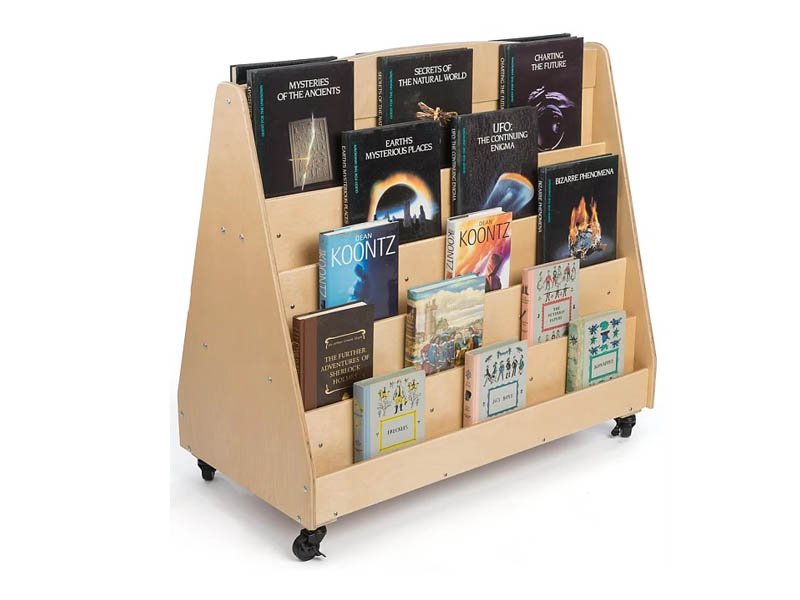

4. How Does MDF Ensure Reliable Flat-Pack Furniture Assembly?

Ever assembled furniture that fell apart after a move? You are not alone. Weak joints can ruin your experience and investment. MDF promises to solve this persistent issue in modern furniture.

MDF supports flat-pack furniture by providing stability and shape retention. Its dense, uniform structure allows panel joints to remain tight and reliable even after repeated assembly and disassembly. This makes MDF ideal when furniture faces various climates before reaching the customer.

Why Stability Matters in Flat-Pack Furniture

When I first assembled flat-pack furniture10, I realized how much force the joints needed to endure. Flat-pack or knock-down furniture is shipped in pieces and assembled on-site, often multiple times. Typical joints—cam locks, confirmat screws, and dowels—help connect panels quickly. However, these joints only perform well if the underlying board resists forces that try to warp or compress it.

MDF, or medium-density fiberboard, stands out here. Its fine fibers and resin binders create a uniform board. Unlike solid wood, MDF has no grain direction. This means repeated tightening of screws or cam locks does not open up cracks or encourage panels to split. The strength remains consistent along the length, width, and thickness. When you move or disassemble furniture, MDF’s shape barely changes.

A Closer Look: Joints and Climate Challenges

Environmental changes also test furniture reliability. Since online orders travel far and sit in various storage environments, furniture panels might see dry cold, humid heat, and frequent temperature shifts. Other materials like plywood or solid wood might swell or shrink. Joint tension suffers, and wobbly shelves become common.

MDF resists these changes. Its internal structure absorbs and releases moisture evenly. Screws remain tight. Cam locks snap into place. Dowel holes do not stretch out of shape. When I helped relocate a friend’s bookshelves from a hot apartment to a cold basement, the MDF panels and joints still fit together perfectly.

Comparing MDF Performance in Panel Joints

| Joint Type | MDF Strength (Repeated Use) | Response to Climate Changes | Common Weaknesses in Other Boards |

|---|---|---|---|

| Cam Lock | High | Very Stable | Splitting/prying in particleboard |

| Confirmat Screw | High | Stable | Stripped holes in solid or plywood |

| Dowel | Moderate-High | Stable | Enlarged holes in plywood, swelling in solid |

MDF keeps flat-pack furniture usable even with frequent moves and climate changes. This is why many worldwide furniture suppliers choose MDF for e-commerce. Joints must remain firm; if the panels deform, assembly becomes painful, and furniture quickly loses value.

I have seen how furniture travelled cross-country for my brother’s new apartment. Packages arrived after days in transit through humid warehouses and cold trucks. When opened, the MDF panels fit like they had left the factory just that morning. All screw and locking points were in line. This level of panel stability was only possible because MDF holds its shape from production to installation.

In summary, MDF helps make flat-pack and modular furniture easy to assemble, sturdy after multiple moves, and resistant to climate stress. If you want furniture that performs wherever life takes you, MDF’s consistency in joint strength plays a vital role.

MDF provides stability and shape retention for flat-pack furniture.True

MDF's dense and uniform structure allows panel joints to remain tight and reliable, even after repeated assembly and disassembly.

MDF is more prone to warping than solid wood when exposed to climate changes.False

MDF resists climate changes better than solid wood, absorbing and releasing moisture evenly without compromising joint integrity.

5. Why Does MDF Resist Warping Better Than Plywood and Particleboard?

Warping ruins straight lines and smooth surfaces. If panels twist or bow, projects look unfinished. Luckily, one material fights this problem better than the others.

MDF resists warping because its uniform fiber structure prevents directional movement. Unlike plywood and particleboard, MDF stays flat and stable, making it the best choice when surfaces must remain smooth and true.

How Different Structures Impact Warping

I have seen wood projects11 fail because a wide board suddenly curves out of place or panel doors no longer close properly after a few months. I have learned that how a board is made decides most of these problems.

Comparing Internal Structure

Let us break down what happens inside each material:

| Property | MDF | Plywood | Particleboard |

|---|---|---|---|

| Core Voids | None | Possible | Possible |

| Surface Uniformity | Very high | Good | Fair |

| Directional Strength | Same in all directions | Strong with wood grain | Weak with chip orientation |

| Risk of Warping | Very low | Moderate | High |

MDF: The Isotropic Advantage

MDF stands for Medium Density Fiberboard12. Manufacturers break wood into tiny fibers then glue and press them into solid sheets. Every square centimeter looks and acts like every other. Because the fibers point in all directions, water and heat do not cause one part to move more than another. In my experience, this means doors, shelf tops, or furniture ends made from MDF rarely bow or twist, even when the seasons change.

Plywood: Crossings and Shrinkage

Plywood tries to resist warping13 by glueing layers at right angles. This works better than single boards from the lumber yard. But plywood sheets can still have small gaps inside. Sometimes, the glue does not saturate every bit, or a knot leaves a hidden hole. When exposed to changes in humidity or pressure, these weak spots can open a path for warping. In one instance, my bookshelf’s plywood sides bent out from the middle after just a year.

Particleboard: Weakest Against Moisture

Particleboard uses wood chips pressed together with glue. Chips are bigger and less uniform than MDF fibers. Gaps between chips trap moisture14. That means a particleboard desk can swell and curl over time. I have replaced drawer bottoms made from particleboard more than once because they sagged under light loads.

Where Flatness Matters Most

Some woodworking jobs demand perfect and lasting flatness15:

- Doors: Warped doors stick and look uneven.

- Drawers: If fronts bend, they catch on the frame.

- Shelving: Bowed shelves sag under the weight.

- Table tops and work surfaces: Dips make work harder and look bad.

If I want assurance that panels will stay straight over time, I use MDF. The extra weight is worth it for smooth edges and no warping, especially in visible or load-bearing applications. For painted or veneered surfaces where stability matters, I never settle for less than MDF’s isotropic reliability.

By choosing the right core, I control not only how good a project looks the first day, but how well it keeps its shape for years. MDF’s uniformity offers peace of mind that alternatives just cannot match.

MDF resists warping better than plywood and particleboard.True

MDF's uniform fiber structure provides stability, preventing directional movement and warping, unlike plywood and particleboard.

Plywood resists warping better than MDF due to its layered structure.False

While plywood has a layered structure, it is not as stable as MDF, which has no core voids and an isotropic composition.

6. How Does Standardization Make MDF Reliable for Furniture Makers?

Designers worry about quality swings and wasted time when materials change. Inconsistent wood can ruin parts and cause delays. Standardized MDF16 offers one answer to this stressful problem.

Standardization ensures MDF’s density, composition, and performance, making it a reliable choice for predictable furniture manufacturing. This reduces risk, waste, and delays, so makers get consistent results in every batch.

What Standards Define MDF Reliability?

Across the world, MDF does not mean the same thing unless producers follow strict standards. There are two main codes. EN 622-517 is used in Europe. ANSI A208.2 is used in the United States. These standards set physical and mechanical requirements for MDF panels. They mainly focus on density range, thickness tolerance, moisture content, and resin loading. Panels that pass these tests give the same results no matter who buys them.

| Key Quality Attribute | EN 622-5 (Europe) | ANSI A208.2 (USA) |

|---|---|---|

| Density (kg/m³) | 600-800 | 600-800 |

| Thickness Tolerance (mm) | ±0.15-0.20 | ±0.125-0.25 |

| Moisture Content (%) | 4-11 | 4-11 |

| Formaldehyde Emission Class | E1, E2 | ULEF, CARB |

Why Are These Standards Important?

In my own work, I learned that if sheet thickness changes, so do the parts. This causes doors not to fit or cabinets not to close. Unpredictable wood knots or splits can lead to wasted money. However, standards force the factory to keep density and resin levels steady. This reduces the chance of soft or brittle spots. I can trust the same cutter settings today and next month. Coating lines require less adjustment. Installers find fewer “surprises” in the field.

How Does Predictable MDF Performance Help in Real Life?

When engineers can count on MDF always measuring 18mm thick, they program their CNC machines just once. There are fewer jams or tool wear issues. The same applies to finishing steps. Paint absorbs evenly. Edges stay smooth because the density does not dip. This repeats from batch to batch. The cost stays low, too, because I can buy bigger lots and know all the panels will fit my plan.

Here’s a quick example from a recent shelving project. I needed panels with a tight fit and no warping. Standardized MDF met the EN 622-5 certification. Every board matched the others, so assembly was smooth and quick. There was almost no scrap.

Table: Standardized MDF Reduces Risks

| Problem Without Standards | Benefits of Standardized MDF |

|---|---|

| Variable shelf thickness | Consistent thickness, no surprises |

| Unpredictable finish | Uniform paint absorption |

| More waste material | Less off-cut, more usable panels |

| Tool and machine wear | Predictable machining performance |

| Delayed project installations | On-time, reliable assembly |

Standardized MDF gives peace of mind. It helps create better products with less risk. Furniture makers depend on this reliability to compete and deliver quality on time. Standards make that possible.

Standardized MDF ensures reliable density and composition across batches.True

Standardization regulates the density, composition, and performance of MDF, ensuring consistent quality in furniture production.

All MDF panels have the same standards worldwide, regardless of manufacturer.False

MDF standards vary by region, such as EN 622-5 in Europe and ANSI A208.2 in the United States, meaning they do not mean the same thing everywhere.

7. How Does MDF Support Greener and Leaner Production?

Furniture makers often struggle with waste and reliance on scarce hardwoods. This causes higher costs and environmental pressure. MDF offers a way to reduce these problems for a more efficient future.

MDF achieves green production by using small logs and wood waste, reducing hardwood demand. Its engineered stability allows for optimized material use and lower rejection rates. Leaner practices and less waste drive sustainable furniture production while conserving natural resources.

Breaking Down MDF’s Sustainable Advantages

Modern furniture faces two challenges at once: sustainable resource use and efficient manufacturing18. Medium Density Fiberboard (MDF) has reshaped how I look at bridging these gaps. MDF’s core value lies in its ability to use wood in ways that traditional boards cannot match.

Efficient Use of Raw Materials

Conventional solid wood panels rely on larger, mature trees to maintain stability. This practice not only limits available resources but also puts old-growth forests at risk. MDF, however, changes this equation.

MDF is engineered using wood fibers from smaller logs and post-industrial wood waste. These would otherwise end up as scrap or even landfill waste. The result is a dramatic reduction in dependence on premium timber. It saves hardwoods while making use of wood that has little value on its own.

Let’s compare:

| Board Type | Material Source | Waste Utilization | Reliance on Hardwood |

|---|---|---|---|

| Solid Wood | Large, mature trees | Low | High |

| MDF | Small logs, wood offcuts | High | Low |

Engineered Stability: Less Waste, Less Rejection

One of the issues in panel manufacture is warping and instability. Panels that move or deform during production end up rejected. This wastes energy, resources, and time. I remember a time in our workshop when a batch of traditional panels twisted as they cured—they had to be discarded, representing a costly loss.

With MDF, its dimensional stability19 takes center stage. There is minimal expansion, contraction, or movement with humidity changes. This means fewer panels fail quality checks. Less rejection during production means less waste of both material and labor.

Supporting Greener Production Practices

MDF’s benefits don’t stop with resource use. Lean production revolves around using only what is needed. MDF’s stable properties help manufacturers cut panels to needed sizes with little offcut. Every piece of material gets used.

These efficiency gains cascade through the value chain:

- Fewer rejected panels means less waste for disposal.

- Smaller logs and waste fibers enter the supply chain, boosting circular use.

- Old-growth forests get relief from timber harvest pressures.

When I assess how MDF fits into modern manufacturing, I see a cycle: efficient, sustainable use of resources leads to stable production and greener outcomes. This turns what was once wood waste into valuable furniture panels, without compromising on stability or quality.

MDF uses wood fibers from smaller logs and post-industrial wood waste to reduce dependence on hardwoods.True

MDF production utilizes lower-quality wood and waste materials, minimizing the exploitation of valuable hardwood forests.

MDF relies on large, mature trees for its primary material, similar to solid wood panels.False

Unlike solid wood panels, MDF is engineered from smaller logs and waste, significantly reducing the need for mature trees.

8. How Does MDF Deliver Long-Lasting Performance in Daily Use?

Many surfaces struggle with nicks, warping, and constant repairs. These issues lead to time-consuming fixes. A stable solution must endure daily use and temperature fluctuations.

MDF’s stable core resists dents and splits, providing a long-lasting, low-maintenance material for high-use areas. This durability translates to fewer repairs, reliable performance, and greater lifespan for furniture and fixtures.

Core Benefits of MDF Stability in High-Use Environments

I have interacted with different wood-based materials through personal projects and collaborative work. Almost every workspace and kitchen I have seen or helped renovate includes areas exposed to heavy, repeated actions. Dents from dropped items, edges that chip from accidental bumps, or surfaces that warp due to inconsistent temperature changes are common sources of frustration. These issues increase repair costs and downtime.

When I learned more about Medium Density Fiberboard (MDF), I found that its engineered core set it apart from many traditional materials in several ways.

MDF Composition20: Consistent and Predictable

MDF is made from fine wood fibers and resin, pressed together at high temperature. This process creates a dense, smooth core that does not have internal gaps or knots. Compared to plywood or solid lumber, MDF's structure means it is less likely to split along grain lines or show surface flaws.

Table: MDF Durability Compared to Other Materials

| Feature | MDF | Plywood | Solid Wood |

|---|---|---|---|

| Core Structure | Uniform | Layered | Natural Grain |

| Resistance to Dents | High | Medium | Variable |

| Splitting/Cracking | Rare | Occasional | Sometimes |

| Response to Temp Changes | Stable | Can Warp | Prone to Warp |

| Maintenance Needs | Low | Moderate | High |

Temperature and Humidity Tolerance

I have placed MDF shelving and cabinetry in both heated offices and humid kitchens. I have seen that MDF does not expand or contract as much as other materials when exposed to these changes. Warping and swelling are rare. This means doors and panels fit well and remain smooth, year after year. In places where the air shifts quickly between hot and cold, like near stoves or windows, MDF often outperforms other options.

Everyday Impact and Wear

Repeated contact from people, appliances, and cleaning tools test any surface. In these settings, even a few millimeters of extra density in MDF make a difference. MDF edges and faces take more hits without showing wear. Unlike wood veneer, which may peel, or particleboard, which may chip, MDF keeps its look and strength. When covered with the right finish or laminate, its maintenance remains as simple as a wipe-down. I have noticed that this reduces the time and energy owners spend fixing or touching up furniture.

Extended Lifespan With Lower Repair Costs

Extending product life does not just benefit appearance. With MDF, fewer repairs mean lower material and labor costs. In institutional or business settings, time saved on maintenance allows for resources to be used elsewhere. Over the years, this makes MDF a smart and cost-saving choice wherever durability and reliability matter most.

When surfaces or cabinetry face daily use and shifting conditions, MDF stands out. Its engineering gives consistent performance and visible benefits that other materials cannot easily match. This is why MDF continues to be trusted in demanding environments where every day is a durability test.

MDF has a stable core that resists dents and splits.True

MDF's engineered core provides high resistance to dents and splits, making it suitable for high-use areas.

MDF is more likely to warp than solid wood.False

MDF is less prone to warping compared to solid wood, especially when exposed to temperature and humidity changes.

Conclusion

MDF's dimensional stability, precision machining, and resistance to warping make it essential for modern furniture, enhancing durability, functionality, and sustainability while supporting contemporary design trends.

-

Exploring this resource will reveal how MDF’s stability can enhance furniture durability and ease of assembly. ↩

-

This link will provide insights into how engineered consistency in MDF leads to superior furniture performance and longevity. ↩

-

Understanding dimensional stability in MDF can help you appreciate its advantages in furniture making, ensuring durability and performance. ↩

-

Exploring the benefits of fiberboard with resin will reveal how this innovation enhances furniture durability and solves common issues. ↩

-

Understanding tight tolerances is key to achieving quality in furniture design, ensuring parts fit perfectly and reducing production issues. ↩

-

Discover the benefits of MDF parts in furniture production, including durability and design flexibility. ↩

-

Explore this link to understand how precision machining enhances furniture design, ensuring quality and creativity. ↩

-

Understanding unstable substrates can help you avoid costly mistakes in your projects. ↩

-

Exploring MDF's benefits can enhance your knowledge of materials for better project outcomes. ↩

-

Learn how to select flat-pack furniture that maintains stability and strength, preventing issues during assembly and relocation. ↩

-

Explore this link to learn effective techniques that can help you maintain the integrity of your wood projects. ↩

-

Explore the advantages of MDF, including its durability and resistance to warping, making it ideal for various woodworking projects. ↩

-

Learn effective techniques to prevent warping in plywood and particleboard, ensuring your projects maintain their shape over time. ↩

-

Understand how moisture affects different materials, helping you choose the right one for your woodworking needs. ↩

-

Discover why maintaining flatness is crucial for woodworking, ensuring your projects are both functional and aesthetically pleasing. ↩

-

Exploring this link will provide insights into how Standardized MDF can enhance quality and efficiency in your projects. ↩

-

Understanding the EN 622-5 standard will help you ensure the reliability and quality of MDF materials in your designs. ↩

-

Learn about the role of efficient manufacturing in promoting sustainability and reducing environmental impact in the furniture industry. ↩

-

Understanding dimensional stability is crucial for manufacturers to minimize waste and improve product quality. ↩

-

Learn about MDF Composition to see why its unique structure offers superior performance compared to traditional materials. ↩