MDF wardrobes are a budget-friendly, versatile option that many find appealing. When I built my first wardrobe, I faced challenges with wood warping and unpredictable costs, issues MDF resolved effortlessly.

People choose MDF for wardrobes due to its cost efficiency, dimensional stability, and superior surface quality for finishing. With excellent machinability and sustainability credentials, MDF meets aesthetic and practical needs, providing customizable, durable, and environmentally friendly wardrobe solutions.

Opting for MDF in wardrobe projects isn't just about cost—it’s about long-term reliability and versatility. This guide will delve into how MDF's unique properties translate into practical benefits for smart, modern wardrobes.

1. How Does MDF Deliver Uniform Quality and Lower Costs for Wardrobes?

Many people overspend on wardrobes but still face inconsistent quality. Frustration grows from wasted materials and unpredictable results. MDF addresses these problems with both cost savings and dependable uniformity.

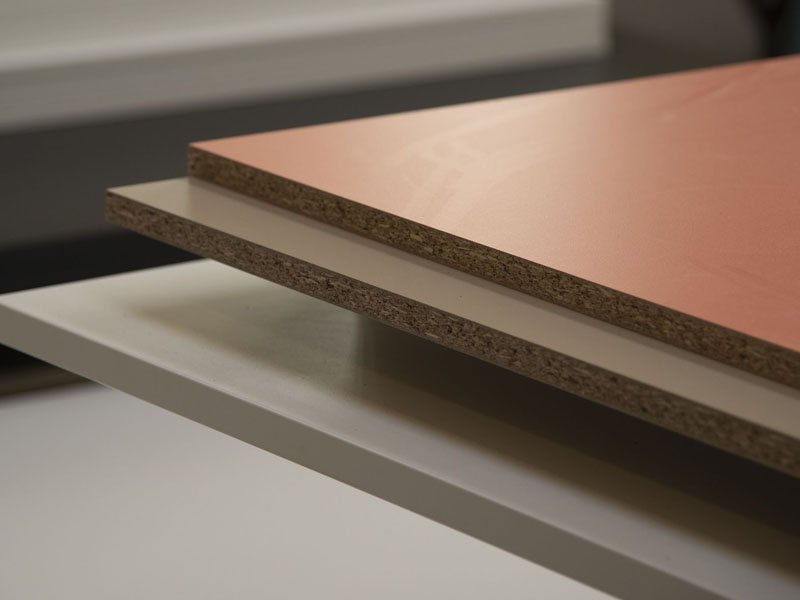

MDF, made from compressed wood fibers, provides wardrobes with a consistent structure, lower production costs, and reliable pricing, outperforming both solid wood and plywood in bulk and custom applications.

Understanding MDF's Cost Efficiency

MDF’s cost efficiency1 stems from its manufacturing process. I have learned that instead of cutting from a single log, MDF uses wood fibers blended with resin2. This mixture forms panels under high pressure. By not relying on large, flawless wood pieces, manufacturers can use a much wider range of wood inputs. These savings go straight into price calculations for wardrobes.

Let’s compare typical material costs in the table below:

| Material | Cost per Sheet (USD) | Material Usage Efficiency | Price Stability |

|---|---|---|---|

| Solid Wood | High | Low | Variable |

| Plywood | Moderate | Moderate | Moderate |

| MDF | Low | High | Stable |

Solid wood often incurs waste. Defects or knots must be cut away. Up to 15% of solid wood can become waste in manufacturing. Plywood still has a layered core which may show voids or inconsistencies, making precision cuts more challenging. MDF, in contrast, is engineered to be free of voids. When I cut MDF for custom wardrobe panels, every piece is usable. That means fewer offcuts and predictable yields.

Uniformity: The Secret to Consistent Results

Uniformity is a hallmark of MDF. Since it is made from fibers rather than planks, each sheet is identical in core density. This leads to sharp, clean edges when cutting. Wardrobe builders find that MDF accepts paint, laminate, and veneer with minimal surface prep. Problems like splitting at edges, common with plywood, rarely occur.

Here is what I notice in custom wardrobe assembly. When using solid wood, grain direction and knots can cause differences from one panel to another. Doors might warp over time if the grain is not oriented correctly. With plywood, the thin veneer surface can occasionally chip or peel. In contrast, MDF remains smooth and even, panel after panel. Hinges and hardware attach securely because MDF does not splinter under pressure.

Predictable Pricing and Bulk Efficiency

One key benefit of MDF is predictability. Because the material is consistent and affordable, wardrobe projects use it for both backs and finished fronts. If a project needs hundreds of identical units, MDF shines. Every sheet performs the same. Wholesalers can offer competitive bids, knowing costs will not unexpectedly rise due to defects or grain selection challenges.

A personal example comes from a recent bulk project. For 100 wardrobe units, MDF allowed me to source every panel precisely cut and ready to finish, resulting in no measurable waste. The pricing estimate I gave held firm to the end, ensuring customer satisfaction.

The Right Choice for Wardrobe Manufacturing

For anyone comparing options, MDF offers a balance that is hard to beat. It is not just about being less expensive. It is also about knowing what to expect in each sheet, in every cabinet, across every job. The uniformity3 of MDF allows for fast, efficient wardrobe production, whether for custom designs or large repeated orders. Solid wood and plywood each have their place, but for predictable cost and quality, MDF remains the industry standard.

MDF provides consistent structure and lower production costs for wardrobes.True

MDF's manufacturing process allows for a uniform core density and reduced waste, leading to cost savings and consistent results in wardrobe production.

MDF is made from solid wood planks and requires large, flawless wood pieces for manufacturing.False

MDF is made from compressed wood fibers mixed with resin, not solid wood planks, which allows for more efficient use of materials and eliminates reliance on flawless wood pieces.

2. Why Is MDF the Best Choice to Prevent Wardrobe Warping?

Humidity can make wooden wardrobes warp, causing frustration and misaligned doors. Many want a solution that protects their wardrobes for years. MDF offers proven dimensional stability.

MDF panels resist warping and swelling thanks to engineered manufacturing, stable thickness, and absence of grain direction. They deliver lasting performance and neat alignment, even in humid settings.

What Causes Warping in Wardrobes?

I used to think any wooden wardrobe was good as long as the wood looked nice. But after years of fighting stuck doors and panels that shifted with each season, I realized natural wood’s charm came with a price. The culprit was always the weather. Humidity made my wardrobe expand in summer and contract in winter, leaving it swollen, warped, or with gaps between panels.

Natural wood contains grain direction, growth rings, and internal stresses. These features make each piece unique. But they also make wood vulnerable to swelling and warping when moisture changes. See how it compares to MDF:

| Property | Solid Wood | MDF |

|---|---|---|

| Grain Direction | Yes | No |

| Response to Humidity | Swells/Warps | Stable |

| Thickness Consistency | Varies | Highly Uniform |

| Panel Flatness | May Distort | Remains Flat |

With solid wood, panels can twist, bow, or misalign, especially in large wardrobes. Even expensive hardware can’t always fix a swollen or bent door.

Why Does MDF Stay Flat and Stable?

I learned that MDF is made from wood fibers bound together under high pressure. This process removes the natural grain. No grain, no problem. Without the internal stresses found in timber, MDF does not “remember” a direction to bend toward.

Every wardrobe panel made from MDF has the same thickness and density. There are no knots or growth rings to cause uneven swelling. Engineers control the moisture and pressure used in MDF’s creation. By doing this, they produce sheets that do not react much to seasonal moisture.

Wardrobes made from MDF have doors that stay aligned. Panels stay flush from top to bottom. There are no gaps or sticky drawers. Even in homes where humidity changes from hot, sticky summers to cold, dry winters, MDF keeps its shape.

Where Does MDF Make the Most Difference?

Big wardrobes show these benefits best. In my own home, a large MDF wardrobe means I can have tall, seamless doors. There are no visible seams or joints that move or open when the weather changes. If you have sliding doors, they keep gliding smoothly.

Uniform panels make it easier to install hardware. Panels align as the designer intended. Edges close neatly, and doors stay square. This reliability saves time and frustration during installation or repairs.

Final Thoughts: Lasting Wardrobes Start with MDF

Choosing MDF for a wardrobe is a smart move. You avoid future repairs and disappointment. MDF does what solid wood cannot: it stands up to humidity, keeps its panels straight, and ensures doors and drawers keep working. For crisp alignment and carefree performance, MDF offers real peace of mind.

MDF panels remain stable and do not warp in humid conditions.True

MDF is engineered to resist warping and swelling due to its uniform material properties and lack of grain direction, making it ideal for humid environments.

Solid wood is more stable than MDF in humid conditions.False

Solid wood is prone to swelling and warping due to its natural grain and moisture sensitivity, unlike MDF, which remains more stable in such conditions.

3. What Makes MDF the Go-To Choice for Seamless Finishes?

Many finishes show flaws or require heavy prep. MDF changes how surfaces look. Its structure gives a solution for sharp, flawless designs, sidestepping issues other boards can’t escape.

MDF’s even fiber structure creates a smooth, flawless surface perfect for paint, laminates, and veneers. It avoids grain telegraphing and raised edges, making it ideal for precise, modern wardrobe designs.

MDF’s Structure: The Foundation of Excellence

I have seen many materials promise a good finish, but few deliver like MDF. The core advantage comes from the internal makeup of the board. MDF stands for medium-density fiberboard4. Each board starts as broken-down wood fibers. Machines compress and bond these fibers under high pressure. This process results in a panel that is uniform from edge to edge and front to back. Tiny fibers fill every gap. No layers, voids, or knots appear within the material.

This uniform makeup brings two major benefits to anyone working with wood surfaces:

- No grain shows through painted or veneered surfaces.

- Edges and corners stay sharp, not fuzzy.

In my experience, other materials have limits that come into play during finishing. Plywood, for example, reveals its layered structure on cut edges. This can make painted edges rough or uneven. Particleboard may show small chips or gaps if not sealed properly. Solid wood introduces wood grain and variation, which sometimes telegraph through thin paints or pressure laminates.

MDF, on the other hand, does not have these problems. Below is a comparison of common wardrobe core materials and their finishing qualities5:

| Material | Surface Smoothness | Edge Quality | Paint/Veneer Outcome |

|---|---|---|---|

| MDF | Excellent | Excellent | Flawless, no grain telegraphing |

| Plywood | Good | Moderate | Layer lines, grain may show |

| Particleboard | Fair | Poor | Gaps, chips, needs heavy prepping |

| Solid Wood | Varies | Good | Grain often visible, may warp |

When I help design minimalist wardrobes6 with sharp geometric lines, only MDF allows for deep profiles and crisp corners straight from the router. No other board matches its smoothness for paint or high-gloss laminates. I can skip heavy sanding and rely on the board to create a glassy surface.

Modern and Minimalist Aesthetics Demands

Current trends call for sleek looks and flawless detail. Any flaw in the material will show on plain, flat panels or around detailed door frames. MDF supports complex shapes and clean, wide surfaces that do not betray tool marks or fiber inconsistencies. This means designers can push creative limits, trusting the board will not fail in the final finish.

As someone who values reliable results, I choose MDF for any project where finish makes the difference between ordinary and exceptional. When the goal is seamless, modern furniture or wardrobe panels, MDF offers both the performance and look required by discerning clients. For flawless finishes and intricate profiles, no other engineered wood performs at this level.

MDF provides a smooth surface that enhances paint and veneer applications.True

MDF's even fiber structure ensures no grain shows through, making it ideal for flawless finishes.

MDF is more prone to visible grain telegraphing than solid wood.False

MDF is specifically designed to avoid grain telegraphing, unlike solid wood which often has visible grain variation.

4. How Does MDF Enable Next-Level Customization in Furniture?

Struggling to create detailed furniture designs? Solid wood has limits and high costs. MDF solves this by allowing precise and flexible machining for intricate customization.

MDF’s consistent density and absence of knots allow precise CNC routing and profiling, making custom details and advanced panel designs not only possible but cost-effective, something solid wood cannot easily achieve.

Understanding Why MDF Excels at Customization

I have worked on wardrobe projects where precise edge profiling was essential. Solid wood often disappointed. Knots, grain differences, and unpredictable density made it tough to achieve a uniform look. But with MDF, I noticed every cut and groove came out as planned. It was a relief.

MDF stands for Medium Density Fiberboard. Its density usually falls between 500 and 850 kg/m³. This means every part of the panel reacts the same way under a blade or CNC router. There are no tough knots or soft spots. As a result, machinists can route out intricate patterns and drill fine holes without worrying about the wood breaking or looking uneven.

The Advantages for Creative Design

When making custom wardrobe doors7, customers sometimes want raised panels or intricate inlays. MDF makes these requests possible. Precision tools can carve out repeated details without losing sharpness or definition. The result is a tailored look that fits personal style and space demands.

Solid wood, by contrast, often restricts design freedom. The cost of materials rises with demanding designs. Machining errors are more likely. Only some expensive timbers can manage a similar performance, and even then, waste rate is higher.

Integrated Moldings Made Simple

Adding moldings directly to furniture panels is another area where MDF stands out. Its even texture allows seamless joins between panels and moldings. No visible gaps, no sanding for hours. Factory operators use edge banders, routers, and drills with MDF every day for this reason.

Comparing Machinability: MDF vs. Solid Wood

| Feature | MDF | Solid Wood |

|---|---|---|

| Knots Presence | None | Common |

| Density Consistency | Very consistent | Varies by area |

| CNC Routing Performance | Highly precise | Varies; grain may split |

| Edge Profiling | Smooth, crisp | May chip or splinter |

| Custom Detailing Cost | Low to moderate | Moderate to high |

My experience makingdecorative wardrobe panels8 confirms the value of this consistency. Every project turns out as sketched, with minimal rework and material loss.

Summary Table: Where MDF Makes Detailing Easy

| Task | MDF Advantage |

|---|---|

| Custom door panels | Precise cuts |

| Integrated moldings | No grain conflict |

| Detailed engraving | No splits |

Final Thoughts

MDF changes furniture production by removing the obstacles of knots and grain. It keeps costs predictable, enables creative freedom, and supports the latest machining technology. For any project where detailing matters, I always consider MDF first. Its machinability gives both professionals and DIY makers new scope for thoughtful, customized work.

MDF provides consistent density, allowing for precise CNC routing.True

No explanation available.

Solid wood has no limitations in detailed furniture design.False

Solid wood has limitations due to its knots and varying density, which can affect the precision required for detailed designs.

5. Why Do Eco-Conscious Buyers Prefer MDF for Their Projects?

Many want stylish furniture without harming nature. Cheap options often hide high costs for the planet. There is an answer for buyers who value both style and sustainability.

Eco-conscious buyers favor MDF because it uses wood residues, supports sustainable forestry, and offers low-emission certifications. These eco-benefits help meet even strict international standards and make it a top choice for reducing environmental impact.

Rethinking Materials: Sustainability of MDF9

I see many people who hesitate to choose furniture made from new materials. They worry about what goes into making them. Is there a way to enjoy good design without damaging the environment? MDF, or Medium Density Fiberboard, can help answer this question.

Many do not know that MDF is made from wood particles often considered waste by sawmills and factories. These include chips, shavings, and fibers too small or irregular for traditional lumber. By using these materials, MDF production helps reduce wasted resources. There is less demand for cutting down fresh trees. Much of the raw material comes from trees or species considered underutilized, which helps support a balanced forest ecosystem. This also provides extra value from managed forests and keeps more land healthy.

Formaldehyde Emissions10: Keeping Indoor Air Safe

You may have heard about formaldehyde emissions from engineered wood. It is a common concern, especially for homes and schools. Older MDF sometimes had high formaldehyde levels that could harm indoor air quality. Today, things have changed.

More MDF products now carry eco-certifications such as E0 or E1. These labels mean the panels release extremely low levels of formaldehyde. Both E0 and E1 standards are recognized worldwide. E0 is the strictest, often required in countries such as Japan, while E1 is also safe for most homes. Furniture and cabinets made from MDF with these ratings keep indoor air safer for everyone.

| MDF Attribute | Environmental Benefit | Buyer Impact |

|---|---|---|

| Wood residues used | Reduces resource waste | Less forest depletion |

| Underutilized species | Promotes forest diversity | Supports eco-credentials |

| E0/E1 certification | Lowers indoor air pollution | Safer for health-conscious families |

| Sustainable sourcing | Maintains healthy forests | Meets green procurement policies |

Why Eco-Labels Matter

Eco-labels are more than just stickers. They signal that a material has undergone testing. Only boards that release formaldehyde at very low rates can carry E0 or E1 marks. Buyers have peace of mind that their choices do not add to indoor pollution11. Institutions and governments often require these certifications in public buildings. This can improve lives on a large scale.

More Than Just a Trend

This focus on sustainability is not new for me. Years ago, I worked with a nonprofit in a region where illegal logging was a serious problem. We saw that using wood residues for products such as MDF helped take pressure off old-growth forests. The shift to eco-certified panels12 has helped many nations control air quality and forest management. It proves that smart design and responsible sourcing can work together.

MDF now stands out for buyers who want furniture or fittings that care for the planet. By asking for MDF with proper certifications, buyers can help support a system that values forests and indoor health. The result is both attractive and ethical, showing that sustainable choices are possible for every home and project.

Eco-conscious buyers prefer MDF because it supports sustainable forestry practices.True

MDF uses wood residues and promotes responsible sourcing, contributing to sustainable forestry efforts.

MDF production significantly increases the demand for cutting down fresh trees.False

In fact, MDF production helps reduce the demand for new timber by utilizing wood residues and underutilized species, thus protecting forests.

6. How Does MDF Provide Superior Hardware Support in Wardrobes?

Weak hardware joints can make wardrobe doors sag or fail over time. This leads to frustration and costly repairs. MDF panels offer a solution with reliable hardware support.

MDF panels have engineered internal strength that firmly supports screws, cams, and hardware. When you use the right fasteners and joining techniques, you can trust MDF for stable, long-lasting wardrobe construction.

Understanding MDF's Core Strength

Medium-Density Fiberboard (MDF)13 is not like solid wood or traditional plywood. MDF is made through a process that bonds wood fibers with resin under high pressure and temperature. This process creates a dense board with an internal bond strength (IB) typically between 0.55 and 0.90 N/mm².

This core strength gives MDF its consistent holding capacity for hardware. When you fix a screw or a threaded cam into MDF, the material grips the hardware all around the thread, unlike some other wood products that may split or crumble. I remember building my first wardrobe with low-grade particle board and ordinary wood screws. The hinges loosened within weeks because the fasteners did not have enough material to bite into. When I switched to quality MDF panels and used confirmat screws, the result was much more solid. The hardware stayed tight, and the doors operated smoothly for years.

The Role of Fastening Techniques

Not every screw or joint method works the same in MDF. Correct hardware selection is essential for optimum performance. The following table shows recommended fasteners and their typical applications:

| Fastener Type | Best Use Cases | Notes |

|---|---|---|

| Confirmat Screws | Side panels, carcase, and shelf joints | Designed for MDF, high grip |

| Hardware Cams | Knock-down wardrobes, quick assembly | Needs precise drilling |

| Glue Blocks | Reinforcing heavy joints, load areas | Always use PVA wood glue |

| Euro Screws | Hinges, drawer runners, adjustable shelves | Do not overtighten |

Proper pilot holes14 are also important. Drilling the right size hole reduces the risk of material splitting and ensures the thread holds tightly. Glue blocks can reinforce corners or spots bearing extra weight, such as under long shelves or near hinge plates for tall wardrobe doors.

Why Consistency Matters for Heavy Use

Heavy wardrobe doors are opened and closed many times each day. If the supporting panels can’t hold screws well, these repeated stresses will loosen hardware. This is even more important for large sliding wardrobes or frequent drawer use. MDF's engineered properties ensure there are no voids or weak spots, so fasteners grip evenly throughout.

For heavier or high-frequency zones (like the hinge side of a wardrobe door), you can also combine confirmat screws with a dab of PVA glue or even glue blocks for added strength. This is the approach I always take for fitted bedroom wardrobes in busy households.

Practical Tips for Maximum Strength

- Always use fasteners designed for engineered boards15 like MDF.

- Drill clean, accurate pilot holes to prevent bursting.

- Reinforce heavy joints with glue blocks when needed.

- Double-check hinge alignment and tightening after installation.

By following these practices and relying on the natural internal strength of modern MDF, you can build wardrobes with hardware joints that remain solid and reliable, even after years of use.

MDF panels provide reliable support for hardware in wardrobe construction.True

MDF's engineered internal strength ensures a solid grip for screws and hardware, contributing to durable wardrobe structures.

MDF is a type of solid wood used in wardrobe making.False

MDF is not solid wood; it is an engineered product made from wood fibers bonded with resin, offering different properties than solid wood.

7. How Does Consistent Material Quality Support Large-Scale Modular Projects?

Material inconsistencies can slow down installation, cause costly errors, and disrupt production. I have seen projects face major delays from mismatched panels or quality defects.

Consistent material quality ensures that every panel fits perfectly and functions as designed, which supports fast assembly, minimizes mistakes, and eases replacement parts sourcing in large-scale or modular furniture projects.

Why IsConsistent Material16 Vital in Modular Systems?

Large-scale modular projects, like wardrobe systems or cabinetry lines, depend on repeatable processes. I once worked with a team building out ten identical rooms for an apartment complex. Our success hinged on receiving MDF panels17 that were exactly alike in each shipment. If a single panel was thicker or denser than the rest, assembly would stall. That risk adds hidden costs and wastes time.

Consistency in material quality means every sheet or panel matches the last in three major ways—thickness, density, and moisture content. Manufacturers use fine controls during MDF production. They measure each batch by machine to meet tight tolerances. For example, a thickness variation of even one millimeter in a wardrobe side panel can prevent doors from closing smoothly or parts from aligning. MDF panels made to strict specs eliminate surprises once the product reaches the assembly line.

What Benefits Does This Bring to the Production Process?

| Key Factor | Impact on Modular Production | Long-Term Advantages |

|---|---|---|

| Thickness Tolerance | Ensures precise fits; fewer errors | Reliable installations |

| Density Consistency | Supports even strength, durability | Fewer rejected parts |

| Moisture Stability | Prevents warping, ensures longevity | Reduces replacement rate |

I remember seeing how uniform panels made us faster on the production floor. Fit checks became automatic. Installers didn’t need to measure each part before putting it in place. That speed made deliveries to clients quicker and projects moved on schedule.

How Does This Affect Replacement and Supply Chains?

Once the first batch of a modular product rolls off the line, future replacements are inevitable. Hinges, drawer faces, and sides may see wear or occasional damage. Consistent material means that replacement parts sourced months or years later will still match the original specs. That is crucial for smart buyers who want to avoid stocking large numbers of spare panels. Instead, they can order replacements on demand, knowing the new parts will fit without extra trimming or modification.

Streamlined supply chains benefit from this approach. When buyers know what to expect from each shipment, they can plan inventories, labor, and delivery windows down to the hour. It reduces wasted time during assembly. Teams spend less time troubleshooting problems.

Why Should Smart Buyers Care About Consistency?

In my experience, the best-run projects focus on eliminating variability in every step. Consistent MDF panels support that goal. They are predictable and easy to work with. Over hundreds or thousands of panels, that predictability saves many hours and reduces headaches. This advantage shows up in lower costs, fewer customer complaints, and higher productivity.

Consistency in material quality is not only a manufacturing achievement. It is the backbone of modern, large-scale modular furniture systems. That is why experienced buyers ask for test reports, specs, and samples. They value tight tolerances and repeatable performance. For any project that needs scale, speed, and reliability, consistency is a must-have requirement.

Consistent material quality in modular projects prevents costly errors and project delays.True

Uniformity in panels ensures precise fits and minimizes the risk of assembly issues, which can lead to delays and extra costs.

Inconsistent material quality has no effect on project timelines.False

Inconsistent materials can lead to mismatched panels and errors, significantly affecting project timelines and causing delays.

8. Why Do Smart Buyers Choose Fire-Resistant MDF Panels?

Moisture and fire risks worry builders and designers. The wrong board can mean repairs and lost safety. Special MDF defends against both. Projects last longer, and spaces stay safer.

Smart buyers pick fire-retardant or moisture-resistant MDF to meet strict safety codes, prevent costly damage, and ensure the longevity of wardrobes near bathrooms or in humid multi-family and hospitality projects.

What Sets Fire-Retardant and Special MDF Apart?

Wardrobes in hotels and apartments face more than just daily wear. Rooms near bathrooms or kitchens can become humid. Codes can demand tougher fire safety. Both of these issues make choosing the wrong MDF costly. I have seen, during site checks, swelling panels and failed inspections ruin schedules.

Understanding Fire-Retardant MDF18

Most fire-resistant MDF uses unique chemicals and fibers. The aim is to slow the spread of flames. Some panels reach EN 13501-1 B-s2,d0, a common benchmark in Europe. This grade means very limited flame spread, little smoke, and no flaming droplets. Few traditional boards offer this level of protection.

Moisture-Resistant MDF19 for Humid Spaces

Panels can fail if not built for moisture. Moisture-resistant MDF uses special resins. These prevent swelling and warping. When I visited a high-end apartment project, I saw wardrobes in bathrooms remain strong after months of damp air. Older types had failed in the same building, splitting and growing mold.

Comparing Key Features

| Feature | Standard MDF | Fire-Resistant MDF | Moisture-Resistant MDF |

|---|---|---|---|

| Flame Spread | High | Very Low (B-s2,d0) | High |

| Smoke Production | Moderate | Low | Moderate |

| Resistance to Humidity | Low | Moderate | High |

| Best Use Case | Dry, low-risk | Required fire safety | Wet, humid areas |

| Typical Locations | Shelving, doors | Hotels, flats, schools | Bathrooms, kitchens |

Why Are These MDF Grades the Smart Choice?

Fire safety rules keep getting stronger. Choosing FR-MDF20 helps avoid expensive upgrades later. It also helps get safety approvals faster. I have seen buyers regret saving a little up front only to be forced to replace panels after a failed safety test.

Moisture-resistant MDF21 also pays off. In wet spaces, it helps prevent swelling and mold. This extends wardrobe life. It can mean no call-backs for repairs and happier tenants.

The Real-World Value

Many projects now use both types together in critical spots. Fire-rated MDF goes in corridors or shared wardrobes. Moisture-resistant panels go where showers and sinks create damp air. I see more spec sheets calling for both. Owners value the peace of mind and longer product life.

To sum up, special-performance MDF may cost more upfront. Over time, it can save much more by protecting projects from damage, legal issues, and safety failures. Smart buyers know the real cost of a mistake. They invest for the long haul—with fire-retardant and moisture-resistant MDF.

Fire-retardant MDF meets strict safety codes to improve safety in construction.True

Fire-retardant MDF is designed to slow flame spread and meet high safety standards, making it a safe choice for construction projects that require compliance with fire safety regulations.

Moisture-resistant MDF is ineffective in preventing warping in humid environments.False

Moisture-resistant MDF is specifically engineered with special resins to prevent swelling and warping, making it effective in humid environments.

9. How Does MDF Deliver Versatility for Custom Wardrobe Designs?

Struggling to match wardrobe style with your vision? Standard materials often force dull or mismatched looks. MDF offers new possibilities for countless textures, finishes, and colors.

MDF enables nearly any wardrobe design by accepting veneers, laminates, and paints easily. This lets users realize customized looks—modern or classic—while keeping costs affordable and results long-lasting.

MDF: The Backbone of Tailored Wardrobe Solutions

When I explored built-in storage for my own home, I noticed how rigid most ready-made wardrobes felt. Limited panel choices, generic finishes, and clashing colors made me hesitate. MDF, or medium-density fiberboard22, changed the game for me and many in my network. It invites creativity—almost every wardrobe vision can come to life with MDF.

Why MDF Works for Diverse Design Styles

MDF stands out because of its smooth, uniform texture. Unlike grain-heavy plywood and natural wood, MDF23 offers a perfect canvas for nearly every finish. You can apply bold paint for a minimalist effect, smooth laminate for a glossy modern look, or a classic veneer for a paneled traditional feel. Every time I have customized a wardrobe, professional finishers quickly achieved the look I wanted, down to unique textures and matching tones.

Simple Comparison: MDF vs Other Materials

| Feature | MDF | Plywood | Solid Wood |

|---|---|---|---|

| Paintability | Excellent, smooth base | Sometimes uneven | Needs prep |

| Veneer Ready | Yes | Yes | Yes |

| Cost | Affordable | Higher | Highest |

| Warp Resistance | High | Moderate | Varies |

| Design Flexibility | Very High | Moderate | Moderate |

Traditional options like solid wood often limit color choices and cost more. Plywood may show seams or textures that clash with modern style. MDF smooths over these problems.

Meeting Custom Needs: Color, Finish, and Detail

Homeowners want wardrobes that express personality. Perhaps you want a deep blue built-in to match coastal decor or a high-gloss white for city living. MDF can be routed for vintage-style panels or left flush for futuristic lines. During a recent consult, I saw an MDF wardrobe painted a deep emerald, its minimalist doors running floor-to-ceiling. Just next door, someone else had used MDF with a warm oak veneer and traditional molding. The same substrate, totally different vibes. Both achieved the exact look they wanted, without spending excessively.

Cost-Effectiveness Without Compromise

Some believe flexibility comes with a high price. That is not true for MDF. Its manufacturing process means large panels can be made without knots or flaws, making it more affordable than premium hardwood. That means more of your budget can go toward unique design elements or clever internal layouts.

The Bottom Line on MDF and Wardrobe Versatility

MDF’s signature strength is flexibility. Modern designers—and detail-focused homeowners—get endless choices for shape, finish, and color. If you want a wardrobe that suits your space and style exactly, MDF delivers—every time, for less.

MDF is a flexible material that allows for customizable wardrobe designs.True

MDF's ability to accept various finishes and colors enables homeowners to create personalized wardrobe styles that meet their aesthetic needs.

MDF adds significant weight to wardrobes compared to solid wood options.False

MDF is generally lighter than solid wood, allowing for easier handling and installation of wardrobe units.

10. Can MDF Wardrobes Really Last and Stay Like New at Home?

Small accidents can make your wardrobe look old fast. Scratches and dents ruin its appeal. There is a way to keep MDF wardrobes looking like new for years.

MDF wardrobes are easy to repair and maintain. Small damages, such as scratches or dents, can be fixed with common fillers and touch-ups. When sealed and cared for well, they last many years, keeping their quality and strength.

How Can MDF Wardrobes Handle Wear and Tear?

Everyday living can be tough on furniture. I have seen how quickly children or moving furniture can mark a wardrobe. MDF, which stands for medium-density fibreboard, might seem fragile. But it surprises most people with its toughness and easy repair process.

Understanding MDF’s Repair Process

MDF is a uniform material without grain or natural knots like solid wood. This structure makes repairs straightforward. When my own MDF wardrobe got a deep scratch, I bought a simple commercial wood filler from a hardware store. I applied it to the scratch, waited for it to dry, and lightly sanded it. Then I touched up the area with matching paint. The damage became almost impossible to see. I found that most damage, like dents from accidental bumps, is just as easy to repair.

Why Longevity Matters in Home Furniture

Long-lasting furniture saves money and reduces hassle. MDF wardrobes, when sealed well, resist moisture and dust penetration. If left unsealed, MDF absorbs moisture and swells. But with the correct sealing during manufacturing and regular cleaning, these problems do not appear. This kind of wardrobe often lasts just as long as more expensive wood. That means less worry about replacing furniture when accidents happen.

Table: Quick Guide to Repairing MDF Wardrobe Damage

| Damage Type | Repair Method | Difficulty | Time Needed |

|---|---|---|---|

| Surface Scratch | Wood filler, touch-up | Easy | 15 minutes |

| Small Dent | Fill, sand, repaint | Easy | 20 minutes |

| Paint Chip | Repaint, seal | Easy | 10 minutes |

| Edge Chip | Filler, sand, seal | Medium | 25 minutes |

Keeping Your MDF Wardrobe at Its Best

Most people worry that MDF will wear out fast. But my experience and that of many furniture owners shows the opposite. With basic care, like keeping the wardrobe dry and cleaning dust often, durability improves. Good sealing on edges and surfaces keeps moisture away. Small repairs keep it looking new. The ability to restore its look with such ease is rare in other materials.

MDF wardrobes can be a wise option for homes. They offer good repairability and surprising longevity for something so simple to care for. This gives peace of mind to anyone who wants both style and staying power.

MDF wardrobes can last many years if properly maintained.True

With proper sealing and regular care, MDF wardrobes resist moisture and maintain their quality over time.

MDF wardrobes are as durable as solid wood without any maintenance.False

MDF requires maintenance to prevent moisture absorption and damage, unlike solid wood which can be more resilient without upkeep.

Conclusion

Smart buyers choose MDF for wardrobes due to its cost efficiency, dimensional stability, superior surface quality, and versatility, making it an ideal material for modern furniture solutions.

-

Exploring this link will provide insights into how MDF's cost efficiency impacts pricing and sustainability in the industry. ↩

-

This resource will help you understand the innovative process behind MDF production and its advantages over traditional wood. ↩

-

Discover how uniformity contributes to consistent results in furniture manufacturing, enhancing quality. ↩

-

Explore this link to understand why MDF is a preferred choice for a smooth finish in woodworking projects. ↩

-

This resource will provide insights into how various materials compare in finishing, helping you make informed choices. ↩

-

Discover expert tips on designing minimalist wardrobes that combine aesthetics with functionality. ↩

-

Discover expert tips on designing custom wardrobe doors that meet your style and functional needs. ↩

-

Explore this link to understand how decorative wardrobe panels can enhance your furniture projects with style and functionality. ↩

-

Explore this link to understand how MDF contributes to sustainable furniture design and reduces environmental impact. ↩

-

Learn more about formaldehyde emissions and their impact on indoor air quality, ensuring a healthier living environment. ↩

-

Learn about the effects of indoor pollution on health and explore effective strategies to minimize exposure in your living spaces. ↩

-

Discover how eco-certified panels contribute to sustainability and responsible sourcing, making a positive impact on the environment. ↩

-

Explore the advantages of MDF in furniture making, including its strength and durability, to enhance your projects. ↩

-

Understanding pilot hole techniques can significantly improve your woodworking projects and prevent material damage. ↩

-

Exploring engineered boards will reveal their advantages, enhancing your knowledge for better construction practices. ↩

-

Understanding the importance of consistent material can help avoid costly errors and delays in your projects. ↩

-

Exploring the benefits of MDF panels can enhance your knowledge of material choices and improve project outcomes. ↩

-

Explore the advantages of Fire-Retardant MDF to ensure safety and compliance in your building projects. ↩

-

Learn how Moisture-Resistant MDF can protect your projects from damage in humid conditions. ↩

-

Explore the advantages of FR-MDF to understand how it enhances fire safety and compliance in your projects. ↩

-

Learn how moisture-resistant MDF can protect your investments and ensure durability in high-humidity environments. ↩

-

Discover the advantages of medium-density fiberboard over traditional materials for creating stylish and functional furniture. ↩

-

Explore this link to understand how MDF can transform your wardrobe design with versatility and style. ↩