1. Is Medium-Density Fiberboard (MDF) Suitable for Outdoor Furniture?

Choosing the right material for outdoor furniture is crucial. Many consider MDF for its cost-effectiveness and finish, yet this choice comes with significant challenges.

MDF is generally unsuitable for outdoor use, primarily due to its high moisture absorption. Even moisture-resistant variants typically fail in harsh weather conditions or high humidity.

Understanding the Challenges with MDF Outdoors

When thinking about materials for outdoor furniture, MDF often comes to mind due to its affordability. However, understanding its limitations is key before making an investment.

MDF Composition and Vulnerability1

MDF is manufactured by binding wood fibers with resin. The process makes it denser than particleboard but also more absorbent. This characteristic poses a problem when exposed to moisture. Unlike solid wood or marine plywood, which naturally resist water, standard MDF absorbs moisture readily. This absorption leads to swelling, loss of structural integrity, and eventual decay. If you live in a rainy or humid area, these effects accelerate.

Moisture-Resistant MDF2: A Better Alternative?

Some manufacturers offer moisture-resistant (MR) MDF. While it is an improvement over standard MDF, its resistance is limited. MR MDF is still primarily designed for indoor use where occasional moisture exposure happens. Extended exposure to outdoor environments, especially in regions with persistent rainfall or high humidity, tests even the moisture-resistant capabilities. As a solution, MR MDF might delay degradation, but it usually doesn't withstand outdoor weather conditions over time.

Comparing MDF with Other Materials

To truly understand where MDF stands, it is beneficial to compare it against more robust outdoor options:

| Material | Moisture Resistance | Durability | Cost |

|---|---|---|---|

| MDF | Low | Low | Low |

| Marine Plywood | High | High | Moderate |

| Solid Wood | Medium to High | High | High |

| HDPE Plastics | High | Very High | Moderate |

Marine plywood3 or solid hardwoods4 with suitable treatments outperform MDF outdoors. They are inherently resistant to moisture, making them ideal for furniture exposed to the elements.

Final Thoughts

In my experience, the choice between MDF and other materials often depends on the intended use and climate. Consider the environmental conditions your furniture will face. MDF is not made for outdoor use over the long term. It might suit temporarily covered or indoor-only outdoor furniture, such as pieces for sunrooms. For more durable and lasting outdoor furniture, it is best to invest in materials designed to resist weathering and moisture.

Thus, while MDF offers a budget-friendly option, in the long run, other alternatives are more suited for permanent outdoor use. Exploring materials that align with outdoor exposure can ensure longevity and a better investment in quality furniture.

MDF is unsuitable for long-term outdoor furniture use due to its high moisture absorption.True

MDF readily absorbs moisture, leading to swelling and decay, particularly in harsh weather conditions.

Moisture-resistant MDF is perfect for permanent outdoor furniture.False

While moisture-resistant MDF is better than standard MDF, it is still designed for indoor use and cannot withstand prolonged outdoor exposure.

2. How Does MDF Compare to Solid Wood and Engineered Panels in Outdoor Durability?

MDF’s durability5 in outdoor furniture is often questioned. Can it withstand the weather like solid wood or engineered panels? Let's explore which materials are best for outdoor conditions.

MDF lacks the natural durability of solid woods like teak, acacia, and eucalyptus, which resist decay and insects. High-pressure laminates and marine-grade plywood also outperform MDF, especially in western and middle eastern market expectations.

Understanding the Durability of Outdoor Furniture Materials

Outdoor furniture needs to endure varying weather conditions. Durability and weather resistance6 are crucial when choosing materials. We need to examine how MDF stands against other options and the expectations in different markets.

Solid Wood’s Natural Advantage

Solid woods like teak, acacia, and eucalyptus dominate the outdoor furniture market. They naturally resist decay and insects. These woods have oils that fight off moisture. This natural protection makes them an excellent choice for outdoor conditions. Here's how their durability compares:

| Material | Natural Resistance | Maintenance Required |

|---|---|---|

| Teak | High | Medium |

| Acacia | Moderate | High |

| Eucalyptus | High | Medium |

Solid wood can be costly, but its benefits often outweigh the price. It reduces long-term costs related to replacements and repairs. The natural aesthetic appeal of solid wood7 also adds value.

Engineered Alternatives: HPL and Marine-grade Plywood

High-pressure laminate (HPL)8 and marine-grade plywood9 are engineered for strength. They boast higher resistance than MDF. These materials are often chosen for their stability under harsh conditions. Here’s a detailed comparison:

| Material | Weather Resistance | Cost |

|---|---|---|

| HPL | High | Moderate |

| Marine Plywood | High | High |

| MDF | Low | Low |

HPL is designed to resist water and UV rays. Marine-grade plywood10 handles moisture better than regular plywood. It uses waterproof adhesives and more robust layers.

MDF: The Compromise

Medium Density Fiberboard (MDF) is affordable. However, it does not naturally resist moisture or insects. To be used outdoors, MDF needs a thorough sealant. Even then, prolonged exposure can warp or degrade it. This need for protection increases maintenance time and cost.

Market Expectations and Consumer Satisfaction

In Western and Middle Eastern markets, customers demand durable outdoor furniture11. These areas face either intense sun or unpredictable weather. Suppliers opting for lower durability materials like MDF might face increased warranty claims and decreased consumer satisfaction.

The choice of material significantly impacts user experience. While MDF can work well indoors, outdoor furniture must meet higher durability standards to satisfy global markets.

Conclusion

In outdoor furniture, the material's ability to withstand various elements is key. While MDF is cost-effective and suits indoor settings, it falls short outdoors. Solid wood and engineered solutions like HPL or marine-grade plywood provide superior durability, meeting the high standards expected by consumers worldwide. These materials might have a higher initial cost, but they reduce maintenance and replacement needs over time.

MDF requires a thorough sealant to be used outdoors.True

MDF does not naturally resist moisture or insects and must be sealed for outdoor use to prevent degradation.

MDF is as durable as solid wood for outdoor furniture.False

MDF lacks the natural durability and resistance to decay and insects that solid wood possesses, making it unsuitable for outdoor conditions.

3. How Do Finishing and Sealing Techniques Influence Outdoor MDF Durability?

MDF's outdoor durability is challenged by moisture. While coatings delay water damage, ultimate resistance is limited. Addressing this, robust finishing solutions are essential.

Proper sealing and finishing can temporarily extend outdoor MDF's life. Yet, exposed edges absorb moisture, undermining long-term durability despite surface coatings.

Exploring MDF and Moisture Vulnerability

Medium-Density Fiberboard (MDF) is widely valued for its smoothness and affordability but it has a notable Achilles' heel: susceptibility to moisture. When used outdoors, this may lead to swelling, warping, and eventual decay. To counteract these vulnerabilities, finishing and sealing are crucial.

Understanding Sealers and Coatings

Industry insights highlight the role of industrial-grade sealers12 and and multi-coat polyurethane finishes13. These coatings serve as protective barriers that reduce moisture ingress. However, they provide only short-term solutions. Here's why they matter:

-

Sealer Composition: Industrial-grade sealers are formulated with chemical compositions that fortify MDF surfaces. Despite preventing immediate water absorption, their effectiveness diminishes over time.

-

Multi-coat Polyurethane: These applications build up layers of defense, slowing down moisture penetration. Yet, they rarely offer the permanence needed for extended outdoor use.

Importance of Edge Sealing

Edges are the most vulnerable parts of MDF. They act as sponges in moist conditions. Comprehensive edge sealing techniques are indispensable:

-

Edge Vulnerability: Unlike flat surfaces, edges lack the natural density to fend off water. This unique characteristic necessitates extra attention compared to only surface sealing.

-

Techniques for Edge Sealing: Edge sealing involves robust, often repeated, application of sealants ensuring they penetrate and protect the porous edges.

Managing Expectations and Maintenance

Understanding the limitations and maintenance needs of MDF is crucial for practical use. Here’s a table summarizing key points:

| Aspect | Consideration |

|---|---|

| Initial Protection | Coat both surfaces and edges with industrial sealants. |

| Maintenance Frequency | Regular inspections and reapplications are essential. |

| Long-term Viability | Ideal for temporary use, not prolonged outdoor placement. |

Long-term exposure to environmental elements, regardless of any sealing method applied, invariably outpaces the protective measures. Thus, routine maintenance14 becomes indispensable. Planning for more frequent refinishing can extend the life expectancy but won't make MDF invincible.

Final Thoughts

Consequently, finishing and sealing techniques15 significantly influence MDF's viability outdoors, acting as yet another reminder of the importance of managing both expectations and ongoing maintenance. Effective sealing and finishing can provide a temporary shield, ensuring that we are prepared for the inevitable reality of MDF’s limitations16.

Proper sealing and finishing techniques can extend the life of outdoor MDF temporarily.True

These techniques create a barrier that delays moisture damage, but their effectiveness is limited over time.

MDF is completely immune to moisture damage when properly finished and sealed.False

Even with proper sealing, MDF remains vulnerable to moisture, especially at exposed edges, which can lead to decay over time.

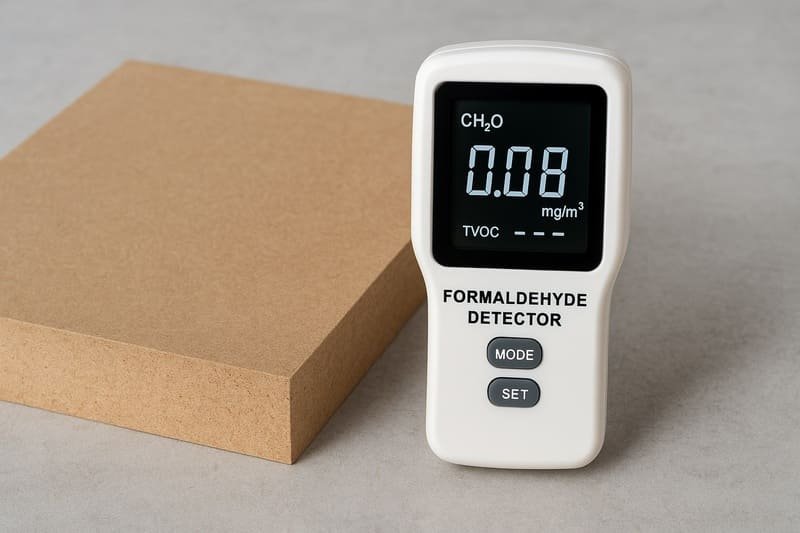

4. How Do European and Australian Regulations Affect Formaldehyde Emissions in Composite Panels?

Stricter environmental rules mean higher compliance costs. This risks businesses' legal standing. Luckily, using low-emission MDF17 ensures practice meets these regulations effortlessly.

European and Australian regulations are tightening around formaldehyde emissions in composite panels. To comply legally, companies need to consider the mandatory use of low-emission MDF as a suitable solution.

Understanding Formaldehyde Restrictions18

Formaldehyde is a common chemical in the production of composite panels. However, it's associated with health hazards which have led to tighter controls. In Europe and Australia, these controls have reached new heights. This change reflects a global shift towards safeguarding health and the environment. But, it puts pressure on companies to comply with new regulations.

Why These Changes Matter

The push for low-emission products is driven by more than just safety concerns. Consumers now demand eco-friendly products19. This demands that businesses provide transparency. Here's where the regulation comes in:

| Region | Regulation Focus | Impact on Production |

|---|---|---|

| Europe | Emission limits on formaldehyde | Need for low-emission MDF |

| Australia | Stringent composite panel standards | Shift to sustainable production |

The enforced limits on emissions ensure reduced exposure to formaldehyde beyond acceptable levels. This means manufacturers must adapt production methods. The emphasis is now to incorporate low-emission MDF20 into their product lines.

Navigating Compliance Challenges

Change can be daunting. For many, transitioning to low-emission MDF requires investment in new technology or materials. The perceived extra cost can be overwhelming. But consider this: non-compliance can lead to fines or market exclusion. The cost of adaptation might be offset by the savings from avoiding penalties.

Furthermore, businesses can capture a growing eco-conscious market. Consumers increasingly prioritize eco-friendly options21. This shift in consumer preferences can boost market presence and potentially lead to increased revenue streams through sustainable practice cheers.

Balancing Costs with Compliance

Adapting to low-emission MDF usage isn't without its challenges. There's the technical transition in manufacturing and the upheaval in supply chains. But it is a necessary evolution. Compliance not only prevents legal backlash but also aligns businesses with consumer values.

Compliance strategies might include:

-

Evaluation of Current Supplies: Businesses should assess their existing MDF supplies to determine which meet new emission standards.

-

Investing in Technology: Updating production methods might be necessary, requiring investment in cleaner production technologies.

-

Partnership with Certified Suppliers: Sourcing materials from certified suppliers can simplify compliance efforts.

The shift towards low-emission MDF in response to European and Australian regulations is an opportunity disguised as a challenge. By adapting, companies position themselves for growth, aligning with regulations and consumer demands. The key is proactive adaptation. Through this, regulations not only shape operating practices but also fuel market competitiveness.

European and Australian regulations require the use of low-emission MDF to meet formaldehyde emission standards.True

These regulations focus on reducing formaldehyde emissions, making low-emission MDF a necessary compliance solution for manufacturers.

Companies can ignore formaldehyde emission regulations without facing any consequences.False

Non-compliance with these regulations can lead to fines and market exclusion, highlighting the importance of adherence.

5. How Does MDF in Outdoor Furniture Affect Profitability and Brand Reputation?

Choosing the right material for outdoor furniture is crucial. MDF may lead to lower upfront costs but can cause issues later.

MDF furniture offers affordability, but its potential for quick deterioration can increase returns and harm brand reputation, particularly where consumers expect durability. For these reasons, selecting more robust materials is advisable.

Understanding the MDF Conundrum

Selecting the appropriate material for outdoor furniture is not just about the initial cost. The lasting impact on your business is significant. Let's delve into the specifics of MDF and its implications.

MDF: What is it?

- Definition: MDF (Medium-Density Fiberboard) is an engineered wood product made by breaking down hardwood and softwood residuals into wood fibers combined with wax and resin binders.

- Advantages: It provides a smooth surface which is perfect for painting, is cost-effective, and is relatively easy to work with.

Market Expectations

When we talk about market expectations in North America and Europe, durability is key. Consumers in these regions often expect their outdoor furniture to withstand varying weather conditions.

- Expectation: The expectation in these markets is clear—durability over the years. Furniture should not only look good but last through different seasons.

- Reality: MDF despite its affordability, may not offer this lasting durability when exposed to outdoor elements such as sunlight, rain, and varying temperatures.

Potential Business Risks

-

Increased Return Rates: Products that fail ahead of time trigger a rise in return rates. This not only affects your inventory but also adds extra customer service costs.

-

Negative Reviews: The power of negative online reviews22 is undeniable. Customers who experience product failure tend to share their experiences widely, damaging the brand's online reputation.

-

Erosion of Brand Trust: Trust is hard to build but easy to lose. Frequent product failures may gradually erode trust in your brand, resulting in lost future sales.

Why Durability Matters

Here's a simple comparison to highlight the importance of durability:

| Feature | MDF Outdoor Furniture | Durable Alternative |

|---|---|---|

| Initial Cost | Lower | Higher |

| Longevity | Shorter, prone to quicker damage | Longer, withstands elements |

| Maintenance | Frequent checks and fixes needed | Minimal upkeep required |

| Customer Feedback | Varied, potentially negative | Often positive |

Solutions for Sustainable Growth

- Invest in Research: Consider in-depth research about materials that offer better longevity.

- Customer Education: Educate customers on the pros and cons of their choices, enabling informed decisions.

- Innovation: Explore innovative designs23 that incorporate more durable materials24 while maintaining aesthetic appeal and cost-effectiveness.

By prioritizing durable alternatives, businesses can not only ensure sustainability but also strengthen their brand trust and profitability for long-term success. Understanding these factors can guide strategic decisions that balance cost with customer satisfaction for optimal business outcomes.

MDF furniture is cost-effective for outdoor use.True

MDF's lower initial costs make it an affordable choice for outdoor furniture, appealing to budget-conscious consumers.

MDF furniture is highly durable and ideal for all outdoor conditions.False

MDF lacks durability and is prone to quick deterioration when exposed to outdoor elements, making it unsuitable for long-term use in varying weather conditions.

6. How Can Sourcing Decisions Improve Outdoor Furniture Performance?

Choosing the right materials for outdoor furniture is crucial, especially in challenging weather conditions. Neglecting this can lead to deterioration and dissatisfied customers. Opt for durable materials to ensure longevity and appeal.

Selecting materials like solid hardwood, treated softwood, and marine plywood for outdoor collections enhances durability, especially in humid or rainy climates. When using MDF, ensure it's MR grade with waterproof finishing, suitable for covered areas. Collaborate with manufacturers for compliance and quality.

Prioritizing Material Selection

Choosing the proper material for outdoor furniture greatly affects its performance and longevity. Solid hardwood, treated softwood, and engineered panels like marine plywood are excellent choices for harsh weather. These materials are naturally resilient. They resist moisture and offer a longer lifespan compared to less robust materials. When I first encountered such materials, I was amazed by their ability to withstand unexpected weather changes without compromising on style or comfort. Let's delve into how each material fits into our sourcing strategy.

-

Solid Hardwood25: Hardwoods like teak or oak are popular. They offer a polished appearance and natural resistance to weathering. Hardwoods age gracefully, often known for enhancing their unique patinas over time.

-

Treated Softwood26: While softwoods like pine are not naturally durable as hardwoods, treating them with preservatives boosts their resistance to moisture and decay. This process is crucial for longevity and ensures that the furniture retains structural integrity.

-

Marine Plywood27: This engineered wood is specially crafted for exterior conditions. It uses moisture-resistant adhesives in its layers, making it ideal for rainy or humid environments. In my experience, marine plywood is versatile and easy to work into modern designs due to its structural stability.

Here's a quick comparison of these materials:

| Material | Durability | Weather Resistance | Maintenance |

|---|---|---|---|

| Solid Hardwood | High | Excellent | Requires occasional sealing |

| Treated Softwood | Medium | Good | Requires regular maintenance |

| Marine Plywood | High | Excellent | Low maintenance |

Strategic Positioning of MDF

When considering MDF, it's essential to understand its limitations. MDF, or Medium-Density Fibreboard, is cost-effective and easy to style, but not naturally resilient against weather. However, the MR ((Moisture Resistant28) grade, paired with waterproof finishes, makes it viable for certain outdoor uses. I remember offering clients a more affordable option with MDF, making it clear that it's perfect for covered patios or balconies where exposure is limited. This understanding helped manage customer expectations effectively.

-

Budget-friendly Option: By positioning MDF as a cost-effective alternative, you can attract budget-conscious consumers29. However, it’s crucial to highlight its limitations, such as its suitability for only covered or transitional spaces.

-

Target Marketing: Transparency in marketing is key. Clearly communicate MDF's best use scenarios, such as sheltered patios. Highlight its aesthetic and affordability, while advising on its limitations for fully exposed environments.

Ensuring Compliance and Quality Control

Collaboration with manufacturers is pivotal in delivering high-quality outdoor furniture. Through quality checks and compliance with market standards, you can maintain a trusted reputation. My collaboration efforts taught me that open communication with manufacturers leads to better material innovation and adherence to standards.

-

Regulations and Standards: Ensuring that products meet market-specific regulations avoids potential legal issues and builds consumer trust.

-

Quality Protocols: Implement rigorous quality control processes for engineered wood products. This includes regular inspection of joints, finishes, and weatherproof coatings.

By focusing on these actionable insights, I've seen how our outdoor collections not only withstand time but delight customers with their durability and design. Choose materials wisely, understand product positioning, and maintain quality standards to foster success in outdoor furniture product lines.

Choosing the right materials significantly enhances the performance and longevity of outdoor furniture.True

Durable materials like solid hardwood, treated softwood, and marine plywood are designed to withstand harsh weather conditions, improving their overall lifespan.

MDF is the best choice for all types of outdoor furniture due to its high durability and weather resistance.False

MDF is not naturally resilient against weather; it requires special treatment to be suitable for outdoor use, making it less ideal than materials like hardwood or marine plywood.

-

Understanding the composition and vulnerabilities of MDF can help you make informed decisions for outdoor furniture. ↩

-

Explore the advantages of Moisture-Resistant MDF to see if it suits your outdoor furniture needs better than standard MDF. ↩

-

Discover why Marine plywood is a top choice for outdoor furniture, offering durability and moisture resistance. ↩

-

Learn about the advantages of solid hardwoods over MDF for outdoor furniture durability and longevity. ↩

-

Understanding MDF's durability is essential for making informed choices about outdoor furniture materials. ↩

-

Exploring weather resistance helps you choose the best materials for outdoor furniture longevity. ↩

-

Exploring the benefits of solid wood furniture can help you understand its long-term value and aesthetic appeal. ↩

-

Learn about HPL's advantages to see why it's a popular choice for durable and stylish surfaces. ↩

-

Discover the unique properties of marine-grade plywood and its applications in harsh environments. ↩

-

Explore the advantages of Marine-grade plywood, known for its superior moisture resistance, making it ideal for outdoor furniture durability. ↩

-

Discover the best materials for outdoor furniture that withstand harsh weather and meet consumer expectations for durability. ↩

-

Learn about industrial-grade sealers and their effectiveness in safeguarding MDF against moisture damage. ↩

-

Discover how multi-coat polyurethane finishes can enhance the moisture resistance of MDF for outdoor applications. ↩

-

Understanding the role of routine maintenance can help you extend the life of MDF and manage its limitations effectively. ↩

-

Exploring effective techniques can enhance MDF's durability outdoors and help you make informed decisions for your projects. ↩

-

Learning about MDF's limitations will prepare you for its use in outdoor settings and help you choose the right materials for your needs. ↩

-

Explore how low-emission MDF can help your business meet environmental standards while reducing costs and improving safety. ↩

-

Stay informed about formaldehyde regulations to ensure your business complies and protects consumer health. ↩

-

Discover the reasons behind the consumer shift towards eco-friendly products and how it impacts businesses. ↩

-

Explore the advantages of low-emission MDF, including compliance benefits and market opportunities for eco-conscious consumers. ↩

-

Discover how eco-friendly options are shaping consumer preferences and driving demand in various industries. ↩

-

Discover the significant effects of negative online reviews on brand reputation and sales, essential for any business owner. ↩

-

Discovering innovative designs can inspire new ideas for sustainable practices that are both appealing and effective. ↩

-

Exploring the benefits of durable materials can enhance your understanding of sustainability and its impact on business success. ↩

-

Explore the advantages of Solid Hardwood, known for its durability and aesthetic appeal, perfect for outdoor furniture. ↩

-

Learn how Treated Softwood enhances the longevity of outdoor furniture, making it a smart choice for various climates. ↩

-

Discover why Marine Plywood is ideal for outdoor furniture, especially in humid conditions, ensuring durability and style. ↩

-

Explore the advantages of Moisture Resistant MDF to understand its suitability for outdoor applications and how it can enhance your projects. ↩

-

Discover strategies to effectively market to budget-conscious consumers and enhance your sales in the furniture industry. ↩